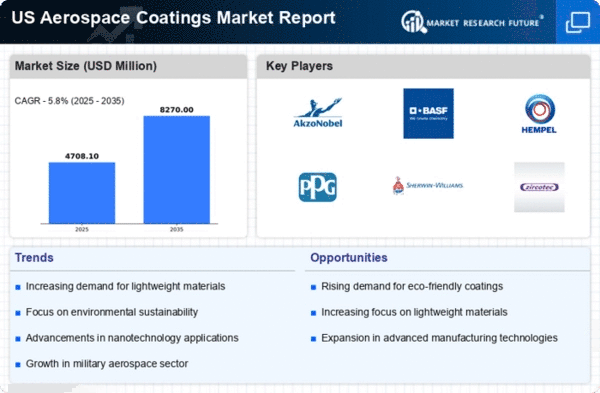

The aerospace coatings market is currently characterized by a dynamic competitive landscape, driven by innovation, sustainability, and technological advancements. Key players such as PPG Industries (US), AkzoNobel (NL), and Sherwin-Williams (US) are actively shaping the market through strategic initiatives. PPG Industries (US) focuses on enhancing its product portfolio with advanced coatings that offer superior performance and environmental compliance. Meanwhile, AkzoNobel (NL) emphasizes sustainability, aiming to reduce its carbon footprint through eco-friendly products and processes. Sherwin-Williams (US) is leveraging digital transformation to optimize its operations and improve customer engagement, thereby enhancing its competitive positioning.The business tactics employed by these companies include localizing manufacturing and optimizing supply chains to enhance efficiency and responsiveness. The market structure appears moderately fragmented, with several players competing for market share. However, the collective influence of major companies like PPG Industries (US) and AkzoNobel (NL) suggests a trend towards consolidation, as these firms seek to strengthen their market presence through strategic partnerships and acquisitions.

In October PPG Industries (US) announced a significant investment in a new manufacturing facility aimed at increasing production capacity for aerospace coatings. This strategic move is likely to enhance PPG's ability to meet growing demand while improving operational efficiency. The investment underscores PPG's commitment to maintaining its leadership position in the market and responding to the evolving needs of aerospace manufacturers.

In September AkzoNobel (NL) launched a new line of sustainable aerospace coatings designed to meet stringent environmental regulations. This initiative not only aligns with global sustainability trends but also positions AkzoNobel as a frontrunner in eco-friendly solutions within the aerospace sector. The introduction of these coatings may attract environmentally conscious customers and enhance the company's reputation in the market.

In August Sherwin-Williams (US) entered into a strategic partnership with a leading aerospace manufacturer to develop innovative coating solutions tailored to specific aircraft requirements. This collaboration is expected to drive product innovation and strengthen Sherwin-Williams' market position by providing customized solutions that meet the unique needs of aerospace clients.

As of November the competitive trends in the aerospace coatings market are increasingly defined by digitalization, sustainability, and the integration of artificial intelligence (AI) in product development. Strategic alliances are becoming more prevalent, enabling companies to leverage complementary strengths and enhance their competitive edge. Looking ahead, it appears that competitive differentiation will increasingly shift from price-based competition to a focus on innovation, technology, and supply chain reliability, as companies strive to meet the evolving demands of the aerospace industry.