Research Methodology on Aerospace Additive Manufacturing Market

The main objective of this research is to provide a comprehensive market analysis of the global aerospace additive manufacturing market and shed insight into the size and trends in the aerospace additive manufacturing market.

To conduct the research, the research methodology adopted in this report comprises both the primary and the secondary research components.

The primary research activities undertaken to prepare the current market report include discussions with market specialists in the industry, like CEOs, decision-makers, market experts, and opinion leaders.

The primary research aims to cover important topics such as market diversification, competitive landscape, size and share of the market, growth drivers, trends, competitive strategies, and other aspects of the global aerospace additive manufacturing market.

The point of contact used in the primary research process was the CMFE Insights employees. The primary research process at CMFE Insights was conducted to validate the data obtained from the secondary sources and gain insight into the market’s performance and dynamics.

Secondary research includes the collation and analysis of market data from industry experts, trade journals, technical publications, etc., by applying different methods and techniques. It also includes a critical review of the information available from secondary sources.

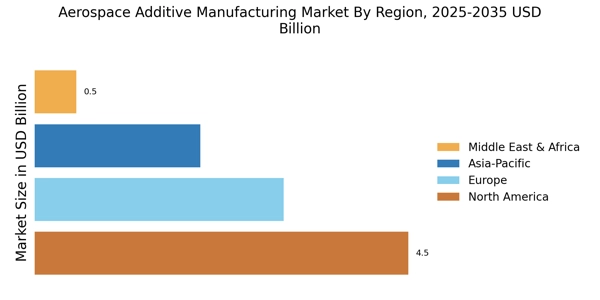

The methodology used in this report also entailed a bottom-up approach as well as a top-down approach. The bottom-up approach was used to size the size of the global aerospace additive manufacturing market. The size of the market from different regions was also estimated using the top-down method.

The market analysis includes the utilization of several factors to arrive at estimates for specific regions. And, to estimate the size of the market in terms of value and volume, the market size estimation incorporates the data obtained from various secondary sources such as industrial databases, and published reports.

The research approach also includes the use of several analytical tools such as SWOT analysis, factor analysis, comparative analysis, and demand and supply side data triangulation. Further, the research employed the use of advanced analytical tools such as the qualitative and quantitative analysis of the global aerospace additive manufacturing market, along with time-series analysis of the market to understand the market dynamics.

The research also includes comprehensive interviews and discussions with the top executives, key players in the aerospace additive manufacturing industry, sales and marketing reps, and industry experts.

These activities were conducted to gain insight into the market conditions and to validate the data obtained from secondary sources as a part of the primary research process.

The research methodology used in this report helps provide an in-depth understanding of the global aerospace additive manufacturing market and forecast for 2023 to 2030. It aims to provide the readers with accurate and reliable market data to make informed decisions.