Russia Ethylene Market Summary

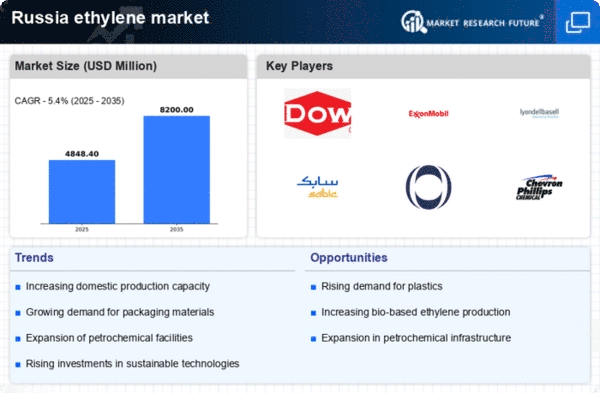

As per Market Research Future analysis, the Ethylene market Size was estimated at 4600.0 $ Million in 2024. The ethylene market is projected to grow from 4848.4 $ Million in 2025 to 8200.0 $ Million by 2035, exhibiting a compound annual growth rate (CAGR) of 5% during the forecast period 2025 - 2035

Key Market Trends & Highlights

The Russia ethylene market is experiencing a shift towards sustainable practices and technological advancements.

- Sustainable production practices are increasingly being adopted across the ethylene market in Russia.

- Technological advancements are driving efficiency and reducing costs in ethylene production processes.

- The petrochemical sector remains the largest segment, while the fastest-growing segment is expected to be bio-based ethylene.

- Rising demand from the petrochemical sector and investment in infrastructure development are key drivers of market growth.

Market Size & Forecast

| 2024 Market Size | 4600.0 (USD Million) |

| 2035 Market Size | 8200.0 (USD Million) |

| CAGR (2025 - 2035) | 5.4% |

Major Players

Dow Chemical (US), ExxonMobil (US), LyondellBasell (US), SABIC (SA), INEOS (GB), Chevron Phillips Chemical (US), Formosa Plastics (TW), Reliance Industries (IN), BASF (DE)