Global Auto OEMs Turn to AI for Predictive Maintenance Integration in 2025

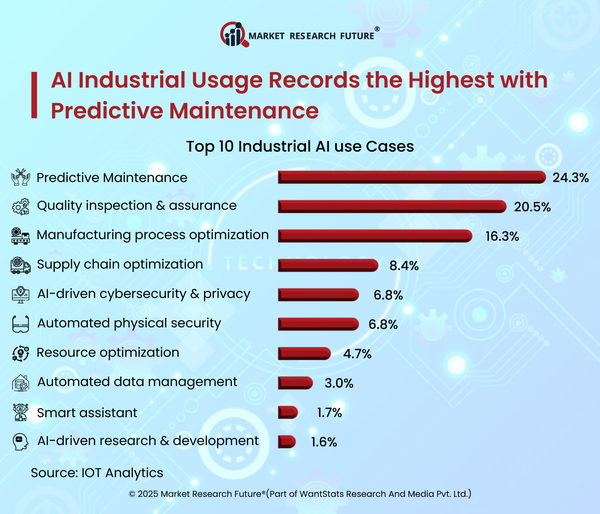

In 2025, global automotive Original Equipment Manufacturers (OEMs) are intensively adopting artificial intelligence (AI) technology in their processes, with predictive maintenance as the primary focus. The predictive maintenance AI system is expected to enhance maintenance scheduling and improve vehicle maintenance reliability, ultimately increasing readiness and customer satisfaction.

AI-based anticipatory maintenance predicts when vehicle system components are likely to fail by utilizing real-time data from vehicle sensors. The breakdown risk of vehicles is significantly reduced, and the timing of breakdowns can be strategically controlled. In 2025, companies like Porsche employed AI systems that track the behavior of high-voltage batteries and warn drivers through apps well in advance. General Motors also provides AI-powered diagnostics using the OnStar system from all its 2025 models. Vehicle servicing and maintenance alerts, along with monthly vehicle wellness checkups, are provided to vehicle owners.

Many Original Equipment Manufacturers (OEMs) are forming partnerships with tech companies to improve their capabilities in Predictive Maintenance Optimization. For instance, Ford has incorporated AI into predictive maintenance systems and driver assistance technologies. The aim is to enhance safety and performance in vehicles. These partnerships help solve large-scale data computations that need advanced algorithms for the maintenance of predictive AI.

In 2025, the automotive industry is expected to undergo significant transformation as AI enhances predictive maintenance capabilities. Original Equipment Manufacturers (OEMs) can now pinpoint potential risks much earlier, allowing for better planning of maintenance costs, improved vehicle safety, and a heightened overall experience for owners. Such benefits support the advancement of connected and autonomous vehicles, which fundamentally depend on real-time data evaluation for proper functioning.

However, these advantages, such as implementing AI-powered predictive maintenance, come with their challenges, particularly with the steep costs associated with technological infrastructure and data security. With advancements in technology and proprietary maintenance frameworks powered by predictive maintenance, Original Equipment Manufacturers (OEMs) will increasingly adopt these frameworks to enhance their operations. The intersection of AI solution technologies with automotive systems is expected to present more evident advantages, such as improved vehicle safety and automotive innovations, by 2025.