Emergence of Industry 4.0

The advent of Industry 4.0 significantly influences the Tension Control Market, as manufacturers increasingly adopt smart technologies and interconnected systems. This new industrial paradigm emphasizes data-driven decision-making and real-time monitoring, which are essential for effective tension control. The integration of Internet of Things (IoT) devices and advanced analytics allows for enhanced performance tracking and predictive maintenance, reducing downtime and improving operational efficiency. The Industry 4.0 trend is expected to propel the Tension Control Market forward, with a projected growth rate of around 9% over the next few years. This shift towards smarter manufacturing processes indicates a promising future for tension control solutions.

Rising Demand for Automation

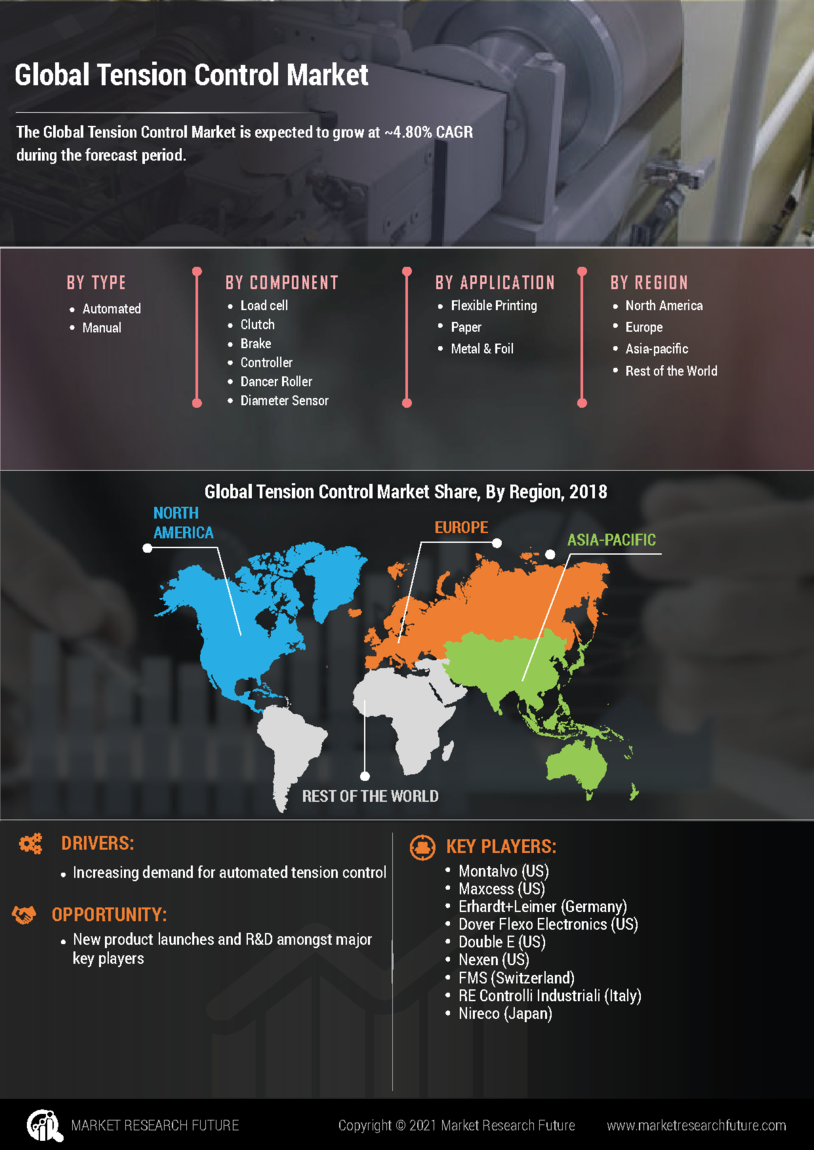

The Tension Control Market experiences a notable surge in demand for automation across various sectors, including manufacturing and packaging. Automation enhances efficiency and precision, which are critical in processes requiring tension control. As industries increasingly adopt automated solutions, the need for advanced tension control systems rises. According to recent data, the automation sector is projected to grow at a compound annual growth rate of approximately 10% over the next five years. This growth directly influences the Tension Control Market, as manufacturers seek to integrate sophisticated tension control mechanisms into their automated systems, ensuring optimal performance and reduced operational costs.

Advancements in Material Science

Innovations in material science significantly impact the Tension Control Market, as new materials offer enhanced properties for tension control applications. The development of lightweight, high-strength materials allows for more efficient tension management in various applications, from textiles to aerospace. These advancements enable manufacturers to produce more durable and reliable tension control systems, which are essential for maintaining product quality and performance. The market for advanced materials is expected to expand, with a projected growth rate of around 8% annually. This trend suggests that the Tension Control Market will benefit from the integration of these innovative materials, leading to improved product offerings and increased market competitiveness.

Growth of E-commerce and Logistics

The Tension Control Market is poised to benefit from the rapid expansion of e-commerce and logistics sectors. As online shopping continues to gain traction, the demand for efficient packaging and shipping solutions increases. Tension control systems play a crucial role in ensuring that products are securely packaged and transported without damage. The logistics industry is projected to grow at a rate of approximately 7% per year, driven by the increasing volume of goods being shipped. This growth presents a significant opportunity for the Tension Control Market, as companies seek to enhance their packaging processes and improve supply chain efficiency through advanced tension control technologies.

Regulatory Compliance and Safety Standards

The Tension Control Market faces increasing pressure to comply with stringent regulatory requirements and safety standards. Industries such as automotive, aerospace, and food processing are subject to rigorous regulations that mandate the use of reliable tension control systems to ensure product safety and quality. Compliance with these standards not only protects consumers but also enhances brand reputation. As regulations evolve, companies within the Tension Control Market must adapt their products and processes to meet these requirements. This necessity for compliance is likely to drive innovation and investment in advanced tension control technologies, ultimately benefiting the market as a whole.