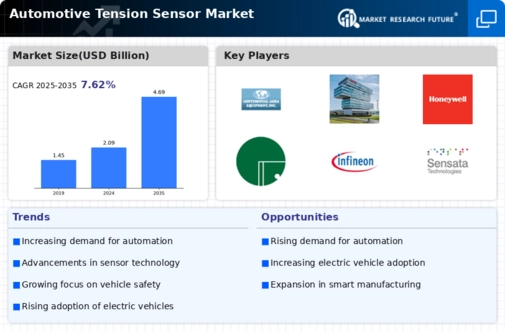

Focus on Safety and Reliability

Safety remains a paramount concern in the automotive sector, driving the Automotive Tension Sensor Market. Tension sensors play a crucial role in ensuring the reliability of various vehicle components, particularly in braking and suspension systems. The increasing emphasis on safety regulations and standards has led manufacturers to invest in high-quality tension sensors that can withstand extreme conditions. According to recent data, the automotive safety systems market is projected to grow at a CAGR of 8% through 2025, indicating a robust demand for reliable tension sensors. This focus on safety not only enhances consumer confidence but also propels the growth of the Automotive Tension Sensor Market.

Shift Towards Electric Vehicles

The transition towards electric vehicles (EVs) is reshaping the Automotive Tension Sensor Market. As automakers pivot to produce more EVs, the demand for specialized tension sensors that can operate efficiently in electric drivetrains is increasing. These sensors are essential for monitoring the tension in various components, ensuring optimal performance and longevity. The EV market is anticipated to grow significantly, with projections suggesting that by 2030, electric vehicles could account for 30% of total vehicle sales. This shift not only opens new avenues for innovation in tension sensor technology but also drives the Automotive Tension Sensor Market forward.

Increased Vehicle Electrification

The trend of vehicle electrification is a pivotal driver in the Automotive Tension Sensor Market. As more manufacturers embrace hybrid and fully electric vehicles, the need for precise tension sensors that can monitor and manage the performance of electric drivetrains becomes critical. These sensors ensure that components operate within optimal tension ranges, thereby enhancing efficiency and reliability. The electrification of vehicles is expected to grow at a CAGR of 15% over the next five years, suggesting a robust market for tension sensors tailored to electric applications. This increased vehicle electrification is likely to stimulate advancements in sensor technology, further driving the Automotive Tension Sensor Market.

Integration of Advanced Technologies

The Automotive Tension Sensor Market is experiencing a notable shift due to the integration of advanced technologies such as IoT and AI. These technologies enhance the functionality and accuracy of tension sensors, allowing for real-time monitoring and predictive maintenance. As vehicles become increasingly connected, the demand for sophisticated sensors that can communicate data seamlessly is rising. This trend is reflected in the projected growth of the automotive sensor market, which is expected to reach USD 30 billion by 2026. The incorporation of smart technologies not only improves vehicle performance but also contributes to overall safety, making it a critical driver in the Automotive Tension Sensor Market.

Rising Demand for Lightweight Materials

The automotive industry is increasingly adopting lightweight materials to enhance fuel efficiency and reduce emissions. This trend significantly impacts the Automotive Tension Sensor Market, as lightweight vehicles require advanced tension sensors that can maintain performance without adding excessive weight. Manufacturers are focusing on developing sensors that are not only lightweight but also durable and reliable. The global market for lightweight materials in automotive applications is projected to reach USD 200 billion by 2025, indicating a substantial opportunity for tension sensor manufacturers. This rising demand for lightweight solutions is likely to propel innovation and growth within the Automotive Tension Sensor Market.