Rising Demand for Lightweight Materials

The Polymer Catalyst Market is experiencing a notable surge in demand for lightweight materials, particularly in the automotive and aerospace sectors. As manufacturers strive to enhance fuel efficiency and reduce emissions, the adoption of lightweight polymers becomes increasingly critical. According to recent data, the automotive sector alone is projected to witness a growth rate of approximately 5% annually, driven by the need for materials that contribute to overall vehicle performance. This trend is likely to propel the Polymer Catalyst Market, as catalysts play a vital role in the synthesis of these advanced materials. Furthermore, the shift towards electric vehicles, which often utilize lightweight components, further emphasizes the importance of polymer catalysts in meeting industry standards and consumer expectations.

Regulatory Pressures and Compliance Standards

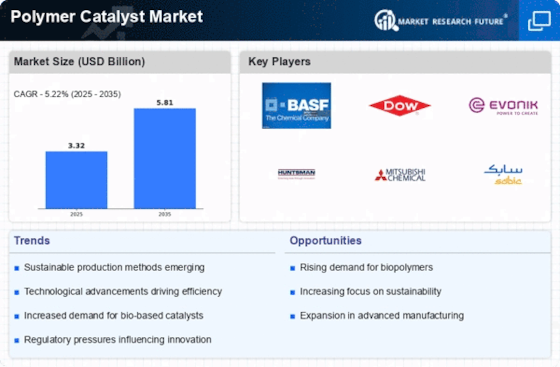

Regulatory pressures and compliance standards are exerting a significant influence on the Polymer Catalyst Market. As governments worldwide implement stricter environmental regulations, manufacturers are compelled to adopt cleaner production methods and materials. This shift is driving the demand for polymer catalysts that facilitate compliance with these regulations, particularly in industries such as automotive, packaging, and construction. Recent data suggests that the market for compliant materials is expected to grow by approximately 5% annually, as companies seek to avoid penalties and enhance their sustainability profiles. Consequently, the Polymer Catalyst Market is likely to see increased investment in research and development to create catalysts that meet evolving regulatory requirements, thereby fostering innovation and market expansion.

Innovations in Polymer Processing Technologies

Innovations in polymer processing technologies are significantly influencing the Polymer Catalyst Market. Advanced techniques such as 3D printing and injection molding are becoming more prevalent, allowing for the efficient production of complex polymer structures. These technologies not only enhance the performance characteristics of polymers but also reduce production costs, making them more accessible to a broader range of applications. Market data suggests that the adoption of these technologies could lead to a compound annual growth rate of around 6% in the polymer processing sector. As manufacturers increasingly seek to optimize their production processes, the demand for effective polymer catalysts that facilitate these innovations is expected to rise, thereby driving market growth.

Sustainability Initiatives and Green Chemistry

Sustainability initiatives are becoming a cornerstone of the Polymer Catalyst Market, as companies increasingly prioritize environmentally friendly practices. The shift towards green chemistry, which emphasizes the use of renewable resources and minimizes waste, is driving the demand for innovative polymer catalysts that align with these principles. Market analysis indicates that the green chemistry sector is expected to grow at a rate of 8% annually, reflecting a broader commitment to sustainability across various industries. This trend not only enhances the appeal of polymer catalysts but also encourages research and development efforts aimed at creating more efficient and eco-friendly catalytic processes. As sustainability becomes a key focus, the Polymer Catalyst Market is likely to benefit from increased investment and innovation.

Increasing Applications in the Electronics Sector

The Polymer Catalyst Market is witnessing a growing interest in the electronics sector, where polymers are increasingly utilized in the production of electronic components. The demand for lightweight, durable, and heat-resistant materials is propelling the use of polymer-based solutions in devices such as smartphones, tablets, and wearables. Recent statistics indicate that the electronics industry is projected to expand at a rate of 7% annually, creating a substantial opportunity for polymer catalysts that enhance the performance and longevity of these materials. As the trend towards miniaturization and enhanced functionality continues, the role of polymer catalysts in developing high-performance electronic materials becomes increasingly vital, thereby contributing to the overall growth of the market.