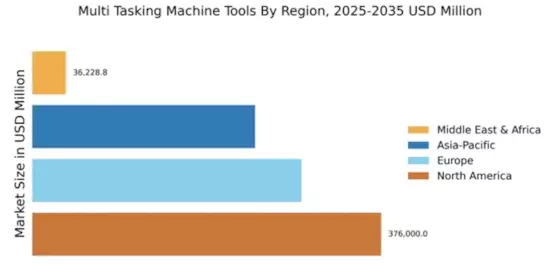

Growth in Emerging Markets

Emerging markets are playing a crucial role in the expansion of the Global Multi-Tasking Machine Tools Market Industry. Countries such as India, Brazil, and Vietnam are experiencing rapid industrialization, leading to increased investments in manufacturing infrastructure. As these nations seek to enhance their production capabilities, the demand for advanced multi-tasking machine tools is expected to rise. This trend is further supported by government initiatives aimed at boosting local manufacturing and attracting foreign investments. Consequently, the market is likely to benefit from the growing industrial base in these regions, contributing to its overall growth trajectory.

Technological Advancements

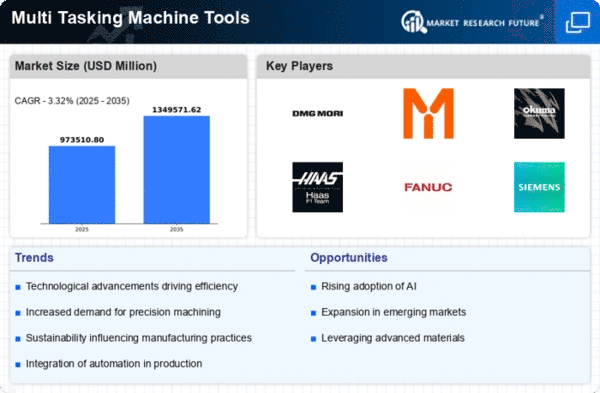

The Global Multi-Tasking Machine Tools Market Industry is experiencing rapid technological advancements, which enhance productivity and efficiency in manufacturing processes. Innovations such as automation, artificial intelligence, and advanced robotics are being integrated into multi-tasking machine tools, allowing for greater precision and reduced cycle times. For instance, the introduction of smart sensors enables real-time monitoring and predictive maintenance, minimizing downtime. As manufacturers increasingly adopt these technologies, the market is projected to grow significantly, with a valuation of 942.2 USD Billion in 2024 and an anticipated increase to 1345.1 USD Billion by 2035, reflecting a robust CAGR of 3.29% from 2025 to 2035.

Rising Demand for Customization

The Global Multi-Tasking Machine Tools Market Industry is witnessing a surge in demand for customized manufacturing solutions. As industries strive for greater flexibility and adaptability, multi-tasking machine tools are increasingly favored for their ability to perform various operations within a single setup. This capability not only reduces lead times but also enhances product quality. For example, the aerospace and automotive sectors are leveraging these tools to produce complex components with intricate designs. This trend is likely to drive market growth, as manufacturers seek to meet the evolving needs of their clients while optimizing production efficiency.

Increased Focus on Sustainability

Sustainability is becoming a pivotal driver in the Global Multi-Tasking Machine Tools Market Industry. Manufacturers are increasingly prioritizing eco-friendly practices, leading to the development of energy-efficient machine tools that minimize waste and reduce carbon footprints. The adoption of multi-tasking machines that utilize advanced materials and processes contributes to sustainable manufacturing. For instance, tools that incorporate recycling capabilities or use renewable energy sources are gaining traction. This shift towards sustainability not only aligns with global environmental goals but also appeals to consumers who are increasingly conscious of the ecological impact of their purchases.