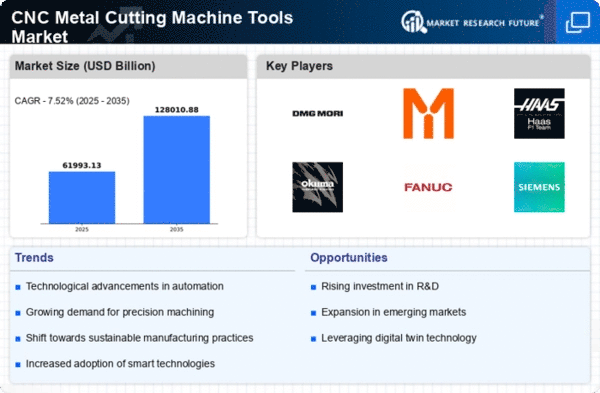

Market Growth Projections

The CNC Metal Cutting Machine Tools Industry is projected to experience substantial growth over the coming years. With an anticipated market value of 1886.3 USD Billion in 2024, the industry is expected to expand significantly, reaching 3995 USD Billion by 2035. This growth trajectory indicates a robust demand for CNC technologies, driven by advancements in manufacturing processes and increasing applications across various sectors. The projected CAGR of 7.06% from 2025 to 2035 further underscores the industry's potential for expansion, reflecting the ongoing evolution of machining technologies and their integration into modern manufacturing practices.

Technological Advancements

The CNC Metal Cutting Machine Tools Industry is experiencing rapid technological advancements, which are enhancing precision and efficiency in manufacturing processes. Innovations such as automation, artificial intelligence, and IoT integration are transforming traditional machining practices. For instance, the introduction of smart CNC machines allows for real-time monitoring and predictive maintenance, reducing downtime and increasing productivity. As a result, manufacturers are increasingly adopting these advanced technologies to remain competitive. The market is projected to reach 1886.3 USD Billion in 2024, driven by the demand for high-performance machining solutions that can meet the evolving needs of various industries.

Growth in Aerospace and Defense

The aerospace and defense industries are pivotal to the Global CNC Metal Cutting Machine Tools Industry, driven by the need for high-precision components and parts. As these sectors continue to expand, the demand for advanced machining solutions is likely to increase. CNC metal cutting tools are essential for producing complex geometries and maintaining stringent quality standards required in aerospace applications. The market's growth is further supported by government investments in defense and aerospace projects, which are expected to bolster the demand for CNC technologies. This sector's expansion may significantly impact the overall market dynamics.

Increasing Adoption of Automation

The increasing adoption of automation in manufacturing processes is a key driver of the CNC Metal Cutting Machine Tools Industry. Automation enhances productivity, reduces labor costs, and improves consistency in production. As manufacturers seek to optimize their operations, the integration of CNC machines with automated systems is becoming more prevalent. This trend is expected to continue, with a projected compound annual growth rate (CAGR) of 7.06% from 2025 to 2035. The shift towards smart factories and Industry 4.0 principles further emphasizes the importance of CNC technologies in achieving operational excellence.

Rising Demand from Automotive Sector

The automotive sector is a significant driver of the CNC Metal Cutting Machine Tools Industry, as it requires precise and efficient machining for components such as engine parts, chassis, and transmission systems. With the ongoing shift towards electric vehicles and lightweight materials, manufacturers are investing in advanced CNC metal cutting tools to ensure high-quality production. This trend is expected to contribute to the market's growth, with projections indicating a rise to 3995 USD Billion by 2035. The automotive industry's increasing focus on automation and efficiency further underscores the importance of CNC technologies in meeting production demands.

Demand for Customization and Flexibility

The demand for customization and flexibility in manufacturing processes is shaping the CNC Metal Cutting Machine Tools Industry. As industries increasingly require tailored solutions to meet specific customer needs, CNC machines offer the versatility to produce a wide range of components with varying specifications. This adaptability is particularly valuable in sectors such as medical devices and consumer electronics, where precision and customization are paramount. The ability to quickly switch between different production runs enhances operational efficiency and responsiveness to market changes, thereby driving the adoption of CNC technologies across various industries.