Market Trends

Key Emerging Trends in the Multi Tasking Machine Tools Market

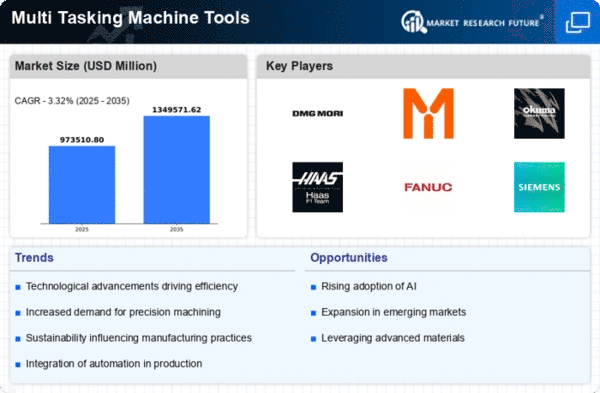

The global surge in manufacturing activities has generated a heightened demand for multi-tasking machine tools, catapulting this market into prominence. Key contributors to this demand include the construction, automotive, and aerospace sectors, which have become pivotal supporters of the multi-tasking machine tools market. The ongoing economic upswing across major economies has substantially propelled global industrial output, fostering an environment conducive to the market's growth. Looking forward, the pace of expansion is expected to further accelerate, driven by the rising demand from end-users and the emergence of new manufacturers in various emerging economies. Countries such as the United States, Canada, Germany, France, Brazil, China, Japan, India, and Southeast Asian nations are poised for substantial growth in the multi-tasking machine tools market. This trajectory is fueled by the rapidly expanding manufacturing base and increased investments in high-performance multi-tasking machine tools. As infrastructure-related industries, including energy, railway, and road construction, undergo significant growth, the automotive sector is also expanding, providing a robust boost to the overall multi-tasking machine tools market. The evolving landscape of these economies points towards a continued and noteworthy evolution of the multi-tasking machine tools market in the coming years. The versatility of multi-tasking machine tools finds wide application across diverse sectors, including automotive, aerospace, construction, and general machinery, thereby fueling market growth. In an era marked by extreme competitiveness, industries strive for heightened productivity and cost efficiency. Multi-tasking machine tools play a pivotal role by offering single-setup complete part machining or facilitating the entire processing journey from raw material to finished part. This efficiency is particularly valuable in industries facing intense competition, where streamlined processes contribute to enhanced productivity and cost-effectiveness. The adoption of advanced manufacturing and machining processes has become integral to reducing machining downtime and optimizing raw material utilization, subsequently minimizing wastage. As a result, industrial operations stand to benefit significantly, maximizing profits for end-users on a global scale during the forecast period. The ability of multi-tasking machine tools to align with modern manufacturing techniques positions them as key enablers for industries seeking to stay competitive, efficient, and economically sustainable. Furthermore, the rise of industrial hubs coupled with growing Foreign Direct Investment (FDI) in major manufacturing sectors across emerging economies adds another layer of impetus to the multi-tasking machine tools market. The influx of investment signals a recognition of the strategic importance of these tools in fostering advanced manufacturing capabilities, enhancing production efficiency, and contributing to overall economic growth. This confluence of factors underscores the optimistic outlook for the multi-tasking machine tools market in the foreseeable future. In conclusion, the global landscape for multi-tasking machine tools is witnessing a robust expansion, driven by the burgeoning manufacturing activities across diverse sectors. The strategic importance of these tools in enhancing productivity, reducing costs, and maximizing efficiency positions them as indispensable assets in the modern industrial landscape. As emerging economies continue to invest in advanced manufacturing capabilities, the multi-tasking machine tools market is poised for sustained growth, offering a dynamic and evolving ecosystem that aligns with the ever-changing needs of the manufacturing sector.

Leave a Comment