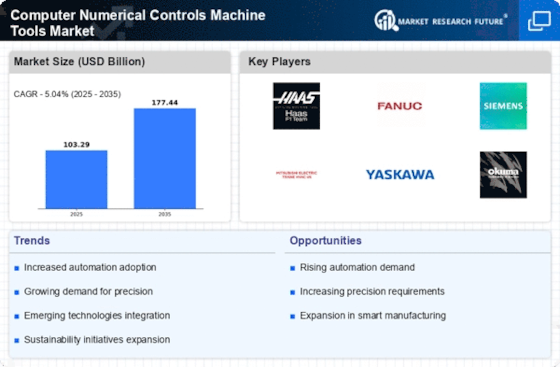

The Computer Numerical Controls (CNC) Machine Tools Market is currently characterized by a dynamic competitive landscape, driven by technological advancements and increasing demand for precision manufacturing across various industries. Key players such as Haas Automation (US), Fanuc (JP), and Siemens (DE) are strategically positioned to leverage innovation and digital transformation to enhance their market presence. These companies are focusing on integrating advanced technologies, such as artificial intelligence and IoT, into their CNC systems, thereby improving operational efficiency and product offerings. This collective emphasis on innovation not only shapes their competitive strategies but also influences the overall market dynamics, fostering a climate of rapid technological evolution.

In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and optimize supply chains. This approach appears to be particularly effective in a moderately fragmented market, where the presence of numerous players allows for varied competitive strategies. The collective influence of key players, including Mitsubishi Electric (JP) and DMG Mori (DE), suggests a trend towards consolidation, as these companies seek to enhance their operational capabilities and market reach through strategic partnerships and acquisitions.

In August 2025, Haas Automation (US) announced the launch of a new line of CNC machines designed specifically for the aerospace sector. This strategic move is significant as it not only diversifies their product portfolio but also positions them to capture a growing market segment that demands high precision and reliability. By focusing on industry-specific solutions, Haas Automation aims to strengthen its competitive edge and cater to the unique needs of aerospace manufacturers.

Similarly, in September 2025, Fanuc (JP) unveiled its latest AI-driven CNC technology, which promises to enhance automation in manufacturing processes. This development is crucial as it aligns with the broader industry trend towards digitalization and smart manufacturing. By integrating AI capabilities, Fanuc is likely to improve operational efficiencies for its clients, thereby reinforcing its market leadership and appealing to manufacturers seeking to modernize their operations.

Moreover, in July 2025, Siemens (DE) entered into a strategic partnership with a leading robotics firm to develop advanced CNC solutions that incorporate collaborative robotics. This collaboration is indicative of a growing trend towards integrating robotics with CNC technology, which could potentially revolutionize manufacturing processes. By enhancing the capabilities of CNC machines through robotics, Siemens is positioning itself at the forefront of innovation in the CNC market.

As of October 2025, the competitive trends within the CNC Machine Tools Market are increasingly defined by digitalization, sustainability, and the integration of AI technologies. Strategic alliances are playing a pivotal role in shaping the current landscape, as companies recognize the need for collaboration to drive innovation and enhance product offerings. Looking ahead, it is anticipated that competitive differentiation will evolve from traditional price-based competition to a focus on technological innovation, reliability in supply chains, and the ability to provide tailored solutions to meet specific industry demands.