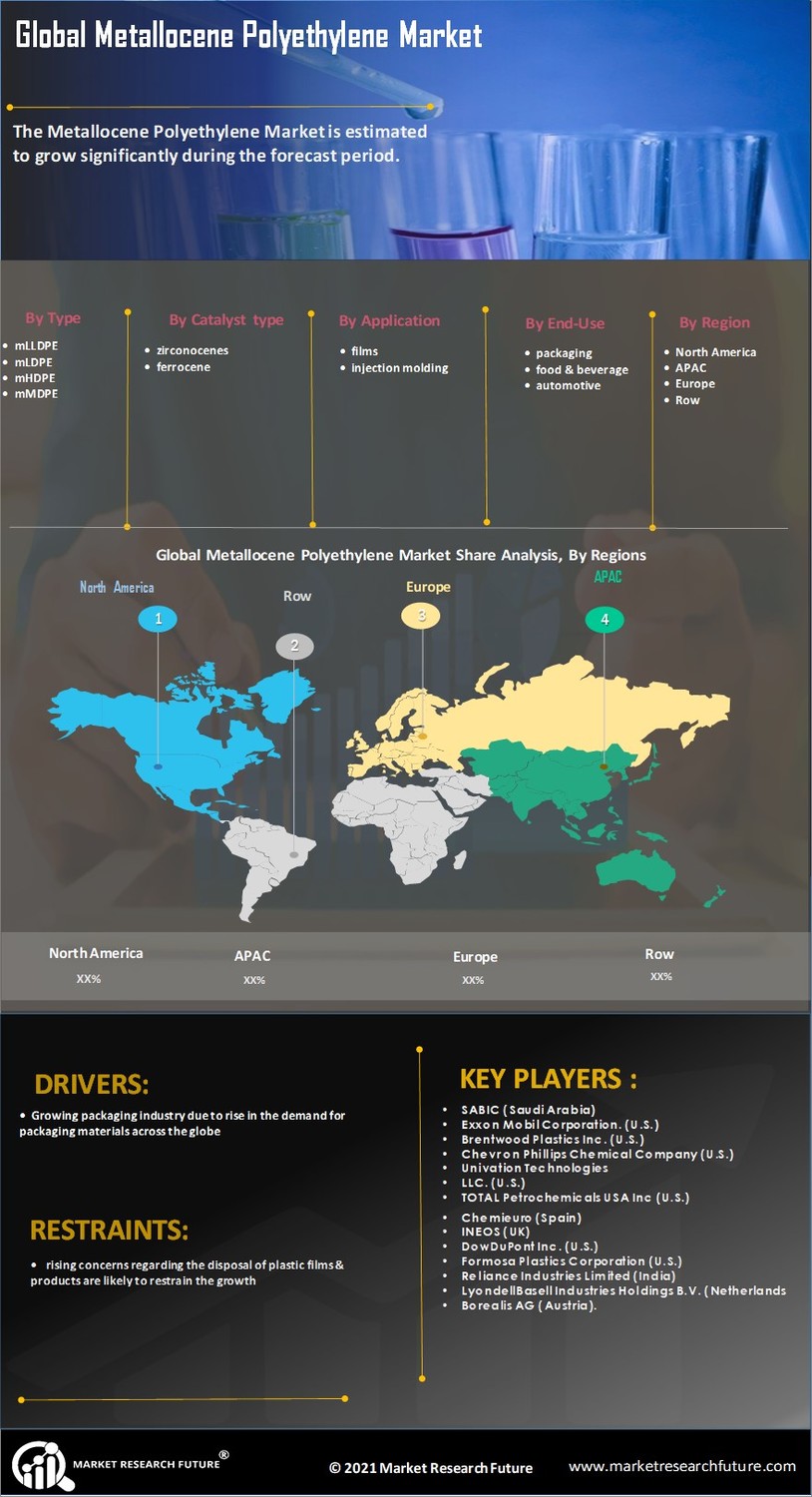

Growth in the Packaging Sector

The packaging sector plays a pivotal role in the expansion of the Metallocene Polyethylene Market. With the increasing emphasis on lightweight and durable packaging solutions, metallocene polyethylene is becoming a preferred choice for manufacturers. This material offers advantages such as reduced material usage and enhanced recyclability, aligning with the growing sustainability trends in packaging. According to recent data, the flexible packaging segment is expected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years, further propelling the demand for metallocene polyethylene. As companies strive to innovate and differentiate their products, the metallocene polyethylene market is poised for significant advancements.

Increasing Focus on Sustainability

Sustainability is becoming a central theme in the Metallocene Polyethylene Market, as consumers and manufacturers alike prioritize eco-friendly materials. Metallocene polyethylene is recognized for its potential to be recycled and reused, which aligns with the global push towards reducing plastic waste. Companies are increasingly investing in sustainable practices, including the development of biodegradable and recyclable metallocene polyethylene products. This shift is likely to attract environmentally conscious consumers and enhance brand loyalty. As sustainability initiatives gain momentum, the metallocene polyethylene market is expected to expand, driven by the demand for greener alternatives in various applications.

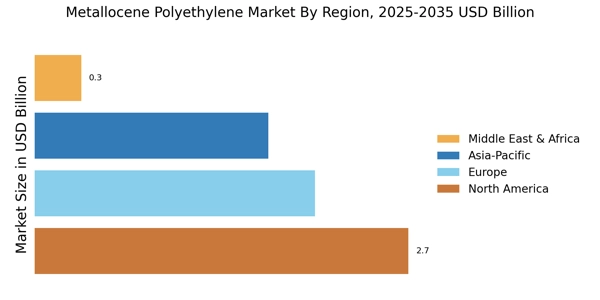

Rising Demand for High-Performance Materials

The Metallocene Polyethylene Market is experiencing a notable increase in demand for high-performance materials across various sectors. This demand is driven by the need for products that offer superior mechanical properties, enhanced clarity, and improved barrier performance. Industries such as packaging, automotive, and construction are increasingly adopting metallocene polyethylene due to its ability to meet stringent performance criteria. For instance, the packaging sector is projected to account for a significant share of the market, as metallocene polyethylene provides excellent sealability and puncture resistance. As manufacturers seek to enhance product quality and performance, the metallocene polyethylene market is likely to witness sustained growth, reflecting the evolving needs of end-users.

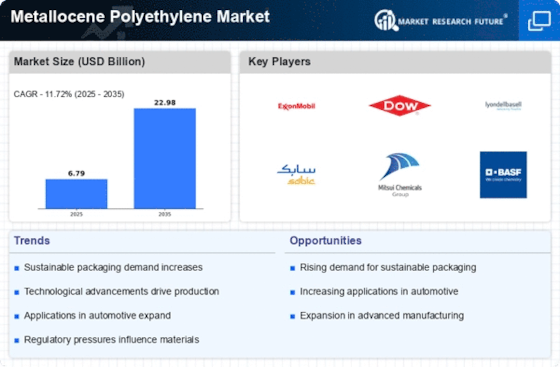

Technological Innovations in Polymer Production

Technological advancements in polymer production are significantly influencing the Metallocene Polyethylene Market. Innovations in catalyst technology and polymerization processes have led to the development of metallocene polyethylene with tailored properties, enhancing its applicability across various industries. These advancements enable manufacturers to produce materials with specific characteristics, such as improved elasticity and thermal stability. Furthermore, the introduction of more efficient production methods is likely to reduce costs and increase the availability of metallocene polyethylene in the market. As a result, the industry is expected to benefit from enhanced production capabilities, which may lead to a broader adoption of metallocene polyethylene in diverse applications.

Expanding Applications in Automotive and Construction

The Metallocene Polyethylene Market is witnessing an expansion of applications in the automotive and construction sectors. In automotive manufacturing, metallocene polyethylene is valued for its lightweight properties, which contribute to fuel efficiency and reduced emissions. Similarly, in construction, this material is utilized for its durability and resistance to environmental factors. The increasing adoption of metallocene polyethylene in these industries is likely to drive market growth, as manufacturers seek materials that enhance performance and sustainability. As the automotive and construction sectors continue to evolve, the demand for metallocene polyethylene is expected to rise, reflecting its versatility and adaptability.