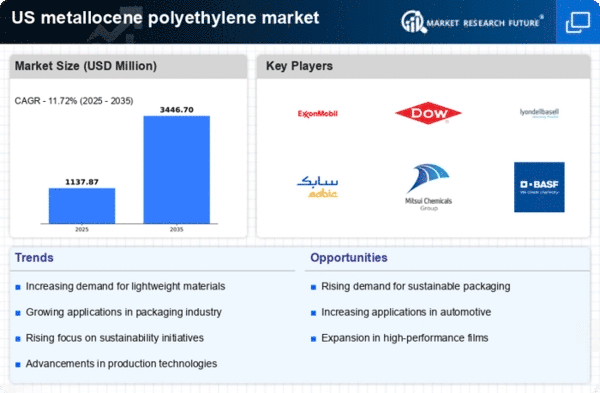

The metallocene polyethylene market exhibits a dynamic competitive landscape characterized by innovation and strategic positioning among key players. Major companies such as ExxonMobil (US), Dow (US), and LyondellBasell (US) are at the forefront, leveraging their technological advancements and extensive production capabilities. ExxonMobil (US) focuses on enhancing its product portfolio through innovative metallocene catalysts, which are pivotal in producing high-performance polyethylene. Meanwhile, Dow (US) emphasizes sustainability, aiming to reduce its carbon footprint by investing in bio-based metallocene polyethylene solutions. LyondellBasell (US) is strategically expanding its manufacturing footprint to meet the growing demand for specialty polymers, thereby reinforcing its market presence.The business tactics employed by these companies include localizing manufacturing and optimizing supply chains to enhance operational efficiency. The market structure appears moderately fragmented, with a few dominant players exerting considerable influence. This competitive environment is shaped by the collective actions of these key players, who are increasingly focusing on technological advancements and sustainability initiatives to differentiate themselves.

In October ExxonMobil (US) announced a partnership with a leading technology firm to develop next-generation metallocene catalysts aimed at improving production efficiency and product performance. This strategic move is likely to bolster ExxonMobil's competitive edge by enabling it to offer superior products that meet evolving customer demands. Similarly, in September 2025, Dow (US) launched a new line of metallocene polyethylene products designed specifically for the packaging industry, which underscores its commitment to sustainability and innovation. This initiative not only enhances Dow's product offerings but also aligns with the growing consumer preference for eco-friendly materials.

In August LyondellBasell (US) completed the expansion of its metallocene polyethylene production facility, significantly increasing its capacity to meet rising market demand. This expansion is expected to enhance LyondellBasell's market share and reinforce its position as a leader in the specialty polymer segment. Furthermore, in July 2025, Chevron Phillips Chemical (US) unveiled a new metallocene polyethylene product line that focuses on high-performance applications, indicating a strategic shift towards catering to niche markets.

As of November the competitive trends in the metallocene polyethylene market are increasingly defined by digitalization, sustainability, and the integration of advanced technologies such as AI. Strategic alliances among key players are shaping the landscape, fostering innovation and enhancing supply chain reliability. The shift from price-based competition to a focus on technological differentiation and sustainable practices is evident. Companies are likely to continue investing in R&D and forming partnerships to stay ahead in this evolving market, suggesting that future competition will hinge on innovation and the ability to meet sustainability goals.