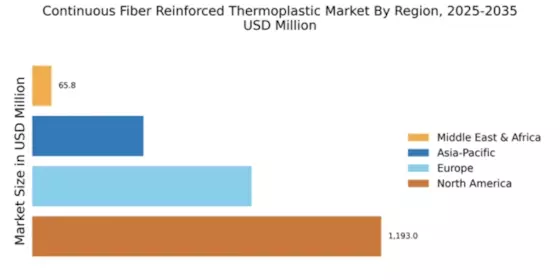

North America : Market Leader in Innovation

North America is poised to maintain its leadership in the Continuous Fiber Reinforced Thermoplastic Market, holding a significant market share of 1193.0 million. The region's growth is driven by increasing demand in automotive and aerospace sectors, alongside supportive regulations promoting lightweight materials. The push for sustainability and energy efficiency further catalyzes market expansion, with companies investing in advanced manufacturing technologies.

The United States stands out as the leading country, hosting major players like Toray Industries and Hexcel Corporation. The competitive landscape is characterized by innovation and strategic partnerships, enhancing product offerings. With a robust supply chain and R&D capabilities, North America is well-positioned to leverage emerging opportunities in the thermoplastic sector.

Europe : Sustainable Growth and Innovation

Europe's Continuous Fiber Reinforced Thermoplastic Market is projected to grow significantly, with a market size of 750.0 million. The region benefits from stringent environmental regulations and a strong focus on sustainability, driving demand for lightweight and durable materials. The automotive and aerospace industries are key growth drivers, as manufacturers seek to enhance fuel efficiency and reduce emissions through advanced materials.

Leading countries such as Germany, France, and the UK are at the forefront of this market, with key players like BASF and Solvay actively investing in R&D. The competitive landscape is marked by collaborations and innovations aimed at meeting regulatory standards. As Europe pushes towards a circular economy, the demand for continuous fiber reinforced thermoplastics is expected to rise, fostering a dynamic market environment.

Asia-Pacific : Rapid Growth and Adoption

The Asia-Pacific region is witnessing rapid growth in the Continuous Fiber Reinforced Thermoplastic Market, with a market size of 380.0 million. This growth is fueled by increasing industrialization and urbanization, particularly in countries like China and India. The demand for lightweight materials in automotive and construction sectors is driving innovation and investment in advanced thermoplastic technologies, supported by favorable government policies.

China leads the region, with significant contributions from local manufacturers and global players like Mitsubishi Chemical Corporation. The competitive landscape is evolving, with a focus on enhancing production capabilities and meeting international standards. As the region embraces technological advancements, the market for continuous fiber reinforced thermoplastics is set to expand further, catering to diverse applications.

Middle East and Africa : Emerging Market Potential

The Middle East and Africa (MEA) region is gradually emerging in the Continuous Fiber Reinforced Thermoplastic Market, with a market size of 65.79 million. The growth is primarily driven by increasing investments in infrastructure and automotive sectors, alongside a rising awareness of the benefits of lightweight materials. Regulatory support for sustainable practices is also contributing to market development, as countries seek to diversify their economies.

Leading countries in this region include South Africa and the UAE, where local manufacturers are beginning to explore advanced materials. The competitive landscape is still developing, with opportunities for international players to enter the market. As the region continues to invest in technology and innovation, the demand for continuous fiber reinforced thermoplastics is expected to grow, presenting new avenues for business expansion.