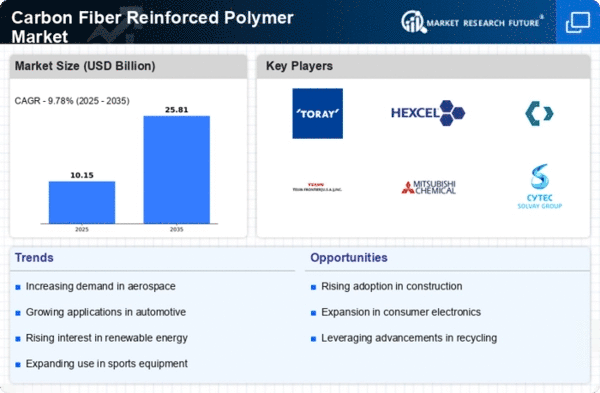

Market Growth Projections

The Global Carbon Fiber Reinforced Polymer Market Industry is poised for substantial growth, with projections indicating a market value of 15.4 USD Billion in 2024 and an anticipated increase to 27.5 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate of 5.4% from 2025 to 2035. The expansion is driven by diverse applications across industries such as aerospace, automotive, and renewable energy, reflecting a growing recognition of the benefits of carbon fiber reinforced polymers. The market's evolution is likely to be influenced by technological advancements and increasing investments in sustainable practices.

Rising Automotive Applications

The automotive industry is a significant driver for the Global Carbon Fiber Reinforced Polymer Market Industry, as manufacturers seek to improve vehicle performance and reduce emissions. Carbon fiber reinforced polymers are being adopted in high-performance vehicles, electric cars, and luxury models due to their superior strength-to-weight ratio. This shift is likely to contribute to a market expansion, with projections suggesting a growth to 27.5 USD Billion by 2035. The increasing focus on lightweight materials aligns with global regulations aimed at reducing carbon footprints, thereby enhancing the appeal of carbon fiber reinforced polymers in automotive applications.

Growing Demand in Aerospace Sector

The Global Carbon Fiber Reinforced Polymer Market Industry is experiencing a surge in demand from the aerospace sector, driven by the need for lightweight materials that enhance fuel efficiency and performance. Carbon fiber reinforced polymers are increasingly utilized in aircraft components, contributing to weight reduction and improved aerodynamics. For instance, major aircraft manufacturers are integrating these materials into their designs, which is projected to propel the market value to 15.4 USD Billion in 2024. This trend is expected to continue as the aerospace industry aims for sustainability and cost-effectiveness, indicating a robust growth trajectory for the Global Carbon Fiber Reinforced Polymer Market Industry.

Increased Investment in Renewable Energy

The Global Carbon Fiber Reinforced Polymer Market Industry is benefiting from increased investments in renewable energy sectors, particularly wind energy. Carbon fiber reinforced polymers are utilized in the production of wind turbine blades, where their lightweight and durable properties enhance efficiency and longevity. As countries strive to meet renewable energy targets, the demand for these materials is expected to rise. This trend not only supports the growth of the carbon fiber market but also aligns with global sustainability goals, indicating a promising future for the Global Carbon Fiber Reinforced Polymer Market Industry as it plays a crucial role in the energy transition.

Advancements in Manufacturing Technologies

Innovations in manufacturing technologies are propelling the Global Carbon Fiber Reinforced Polymer Market Industry forward. Techniques such as automated fiber placement and 3D printing are enhancing production efficiency and reducing costs associated with carbon fiber components. These advancements allow for more complex designs and applications across various industries, including construction and sports equipment. As these technologies mature, they are expected to attract investments and drive market growth, potentially achieving a compound annual growth rate of 5.4% from 2025 to 2035. This evolution in manufacturing processes is likely to broaden the scope of carbon fiber applications.

Emerging Applications in Sports and Leisure

The Global Carbon Fiber Reinforced Polymer Market Industry is witnessing growth due to emerging applications in the sports and leisure sectors. High-performance sporting goods, such as bicycles, tennis rackets, and fishing rods, increasingly incorporate carbon fiber reinforced polymers for their lightweight and high-strength characteristics. This trend is likely to expand as consumers demand more advanced and durable products. The market's expansion in this area not only reflects changing consumer preferences but also indicates a broader acceptance of carbon fiber materials across various recreational activities, further solidifying its position in the Global Carbon Fiber Reinforced Polymer Market Industry.