Cost-Effectiveness

Cost considerations are increasingly influencing the Long Fibre Reinforced Thermoplastic Composites Market. The ability to produce high-performance materials at competitive prices is essential for manufacturers aiming to capture market share. Long fibre reinforced thermoplastics offer a favorable cost-to-performance ratio, making them an attractive option for various applications. Additionally, advancements in production techniques are contributing to lower manufacturing costs, which can enhance profitability for companies in this sector. Market analysis indicates that the cost of long fibre reinforced thermoplastic composites is expected to decrease by approximately 5 to 7% over the next few years, further driving adoption across industries. This cost-effectiveness is likely to bolster the Long Fibre Reinforced Thermoplastic Composites Market.

Regulatory Support

Regulatory frameworks are increasingly favoring the use of long fibre reinforced thermoplastic composites, providing a supportive environment for the Long Fibre Reinforced Thermoplastic Composites Market. Governments worldwide are implementing policies that promote the use of advanced materials in various applications, particularly in sectors like automotive and construction. These regulations often focus on enhancing safety, performance, and environmental sustainability. For instance, initiatives aimed at reducing carbon emissions are encouraging manufacturers to adopt lightweight materials, such as long fibre reinforced thermoplastics. This regulatory support not only facilitates market entry for new players but also encourages existing companies to innovate and expand their product offerings within the Long Fibre Reinforced Thermoplastic Composites Market.

Technological Innovations

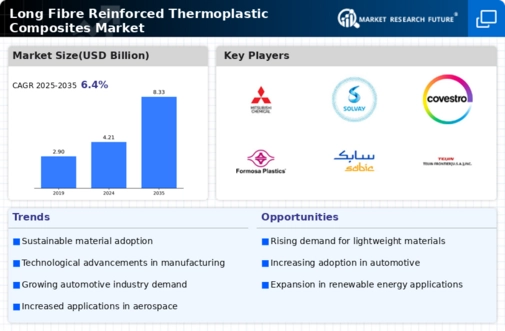

Technological advancements play a crucial role in shaping the Long Fibre Reinforced Thermoplastic Composites Market. Innovations in manufacturing processes, such as improved injection molding techniques and advanced fibre treatment methods, enhance the performance and durability of these composites. Furthermore, the integration of automation and smart technologies in production lines is streamlining operations, reducing costs, and increasing efficiency. Recent data indicates that the adoption of such technologies could lead to a reduction in production time by up to 30%. As these technologies continue to evolve, they are likely to drive further growth and competitiveness within the Long Fibre Reinforced Thermoplastic Composites Market.

Sustainability Initiatives

The Long Fibre Reinforced Thermoplastic Composites Market is experiencing a notable shift towards sustainability. As environmental concerns intensify, manufacturers are increasingly adopting eco-friendly materials and processes. This trend is driven by regulatory pressures and consumer demand for sustainable products. The use of long fibre reinforced thermoplastics, which can be recycled and have a lower carbon footprint compared to traditional materials, aligns with these sustainability goals. In fact, the market for sustainable composites is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 10% in the coming years. This focus on sustainability not only enhances brand reputation but also opens new avenues for innovation within the Long Fibre Reinforced Thermoplastic Composites Market.

Diverse End-Use Applications

The versatility of long fibre reinforced thermoplastic composites is a significant driver for the Long Fibre Reinforced Thermoplastic Composites Market. These materials find applications across various sectors, including automotive, aerospace, construction, and consumer goods. In the automotive sector, for instance, the demand for lightweight and high-strength materials is surging, as manufacturers seek to improve fuel efficiency and reduce emissions. Reports suggest that the automotive segment alone could account for over 40% of the market share by 2026. This broad applicability not only enhances market potential but also encourages innovation and development within the Long Fibre Reinforced Thermoplastic Composites Market.