Increased Focus on Aircraft Performance

The aviation carbon fiber Market is driven by an increased focus on enhancing aircraft performance. Airlines and manufacturers are continually seeking ways to improve speed, agility, and overall efficiency. Carbon fiber composites play a crucial role in achieving these performance metrics due to their high strength-to-weight ratio and durability. As aircraft become more advanced, the demand for materials that can withstand extreme conditions while contributing to overall performance is paramount. This trend is likely to propel the Aviation Carbon Fiber Market forward, as manufacturers increasingly incorporate carbon fiber into their designs to meet the evolving demands of the aviation sector.

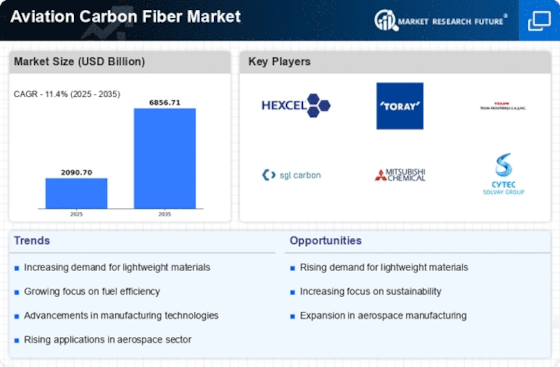

Growing Demand for Lightweight Materials

The Aviation Carbon Fiber Market is experiencing a surge in demand for lightweight materials, driven by the need for fuel efficiency and reduced emissions in aviation. Carbon fiber composites are significantly lighter than traditional materials, which can lead to substantial weight savings in aircraft design. This weight reduction not only enhances fuel efficiency but also contributes to lower operational costs for airlines. According to recent data, the aviation sector aims to reduce fuel consumption by 20% by 2030, which further propels the adoption of carbon fiber materials. As airlines and manufacturers prioritize sustainability, the Aviation Carbon Fiber Market is poised for growth, as these materials align with the industry's goals of minimizing environmental impact while maximizing performance.

Rising Investment in Aerospace Innovation

The Aviation Carbon Fiber Market is witnessing a rise in investment directed towards aerospace innovation. As the aviation sector evolves, stakeholders are allocating resources to research and development initiatives aimed at exploring new materials and technologies. This investment is crucial for advancing the capabilities of carbon fiber composites, making them more accessible and effective for aviation applications. Recent reports indicate that R&D spending in the aerospace sector is projected to increase by 15% over the next five years, which could significantly impact the Aviation Carbon Fiber Market. As innovation continues to flourish, the market is likely to expand, driven by the introduction of cutting-edge carbon fiber solutions.

Advancements in Manufacturing Technologies

The Aviation Carbon Fiber Market is significantly influenced by advancements in manufacturing technologies that enhance the production of carbon fiber composites. Innovations such as automated fiber placement and 3D printing are streamlining the manufacturing process, reducing costs, and improving the quality of carbon fiber components. These technological improvements enable manufacturers to produce complex geometries that were previously challenging to achieve, thus expanding the application of carbon fiber in aviation. As production becomes more efficient, the Aviation Carbon Fiber Market is expected to grow, as manufacturers can offer competitive pricing while maintaining high performance standards in aircraft design.

Regulatory Support for Emission Reductions

The Aviation Carbon Fiber Market benefits from increasing regulatory support aimed at reducing carbon emissions in the aviation sector. Governments and international organizations are implementing stringent regulations that mandate lower emissions from aircraft. This regulatory landscape encourages manufacturers to adopt advanced materials like carbon fiber, which can help meet these requirements. For instance, the International civil aviation Organization has set ambitious targets for reducing greenhouse gas emissions, which has led to a heightened focus on innovative materials. Consequently, the Aviation Carbon Fiber Market is likely to see a rise in demand as manufacturers seek to comply with these regulations while enhancing aircraft performance and efficiency.