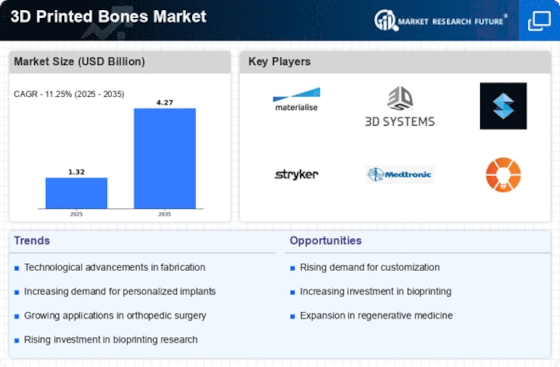

Rising Demand for Bone Implants

The increasing prevalence of orthopedic disorders and the aging population are driving the demand for bone implants. The 3D Printed Bones Market is witnessing a surge in demand as traditional bone grafting methods are often limited by availability and compatibility issues. According to recent data, the orthopedic implant market is projected to reach USD 60 billion by 2026, indicating a robust growth trajectory. This trend suggests that the 3D Printed Bones Market could capture a significant share of this expanding market, as customized solutions offer improved patient outcomes and reduced recovery times. Furthermore, the ability to create patient-specific implants enhances the overall effectiveness of surgical procedures, making 3D printed solutions increasingly attractive to healthcare providers.

Technological Advancements in 3D Printing

Technological innovations in 3D printing are revolutionizing the production of bone implants. The 3D Printed Bones Market benefits from advancements in materials and printing techniques, which enhance the quality and precision of printed bones. Recent developments in biocompatible materials allow for better integration with human tissue, thereby improving the success rates of implants. The market is expected to grow as these technologies become more accessible and cost-effective. For instance, the introduction of metal 3D printing has expanded the range of applications for orthopedic implants, potentially increasing the market size significantly. As these technologies evolve, they are likely to drive further investment and interest in the 3D Printed Bones Market.

Growing Awareness of Personalized Medicine

The shift towards personalized medicine is influencing the 3D Printed Bones Market significantly. Patients and healthcare providers are increasingly recognizing the benefits of tailored medical solutions that cater to individual needs. This trend is particularly relevant in orthopedic surgery, where the customization of bone implants can lead to better surgical outcomes. The market is responding to this demand by offering solutions that are specifically designed for each patient, which may enhance recovery times and reduce complications. As awareness of personalized medicine continues to grow, the 3D Printed Bones Market is likely to see an uptick in demand for customized implants, further solidifying its position in the healthcare landscape.

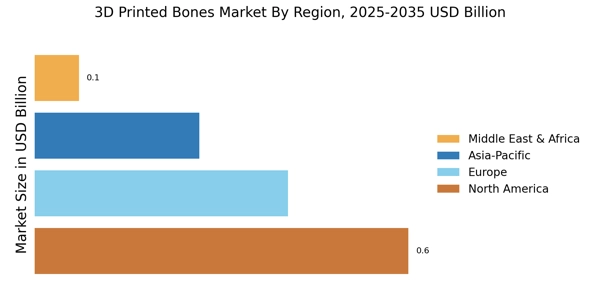

Increasing Investment in Healthcare Infrastructure

Investment in healthcare infrastructure is a critical driver for the 3D Printed Bones Market. Governments and private entities are increasingly allocating funds to enhance healthcare facilities, which includes the adoption of advanced technologies like 3D printing. This trend is particularly evident in regions where healthcare systems are undergoing modernization. The World Health Organization has reported that healthcare spending is expected to rise, with a focus on innovative solutions that improve patient care. As hospitals and clinics upgrade their capabilities, the demand for 3D printed bone implants is likely to increase, thereby expanding the market. This investment not only supports the growth of the 3D Printed Bones Market but also fosters a more efficient healthcare delivery system.

Regulatory Support for Innovative Medical Solutions

Regulatory bodies are increasingly supporting the development of innovative medical solutions, which is beneficial for the 3D Printed Bones Market. Streamlined approval processes for 3D printed medical devices are encouraging manufacturers to invest in research and development. This regulatory environment fosters innovation and allows for quicker market entry of new products. For instance, the FDA has established guidelines that facilitate the approval of 3D printed implants, which could lead to a more dynamic market landscape. As regulations evolve to accommodate technological advancements, the 3D Printed Bones Market is likely to experience accelerated growth, as companies can bring their innovative solutions to market more efficiently.