Market Growth Projections

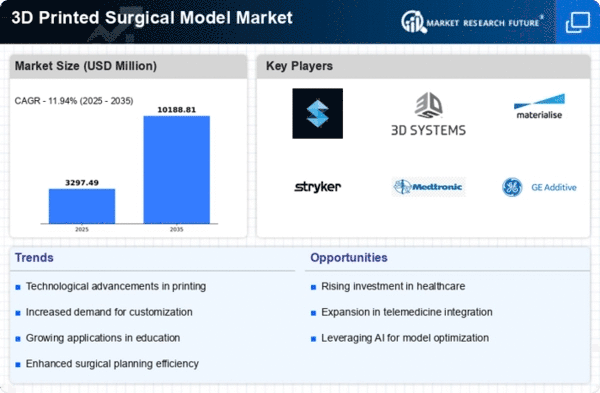

The Global 3D Printed Surgical Model Market Industry is poised for substantial growth, with projections indicating a market size of 2.95 USD Billion in 2024 and an anticipated expansion to 10.2 USD Billion by 2035. This growth trajectory reflects a compound annual growth rate (CAGR) of 11.93% from 2025 to 2035, highlighting the increasing adoption of 3D printing technologies in surgical applications. The market dynamics suggest a robust demand driven by technological advancements, personalized medicine, and the need for cost-effective solutions in healthcare.

Cost-Effectiveness of 3D Printing

The Global 3D Printed Surgical Model Market Industry benefits from the cost-effectiveness associated with 3D printing technologies. Traditional methods of creating surgical models can be labor-intensive and expensive. In contrast, 3D printing streamlines the production process, reducing both time and costs. This economic advantage is particularly appealing to healthcare institutions looking to optimize their budgets while maintaining high standards of care. As the market continues to grow, the expected compound annual growth rate (CAGR) of 11.93% from 2025 to 2035 suggests that more healthcare providers will adopt 3D printing to enhance their operational efficiency.

Rising Demand for Personalized Medicine

The Global 3D Printed Surgical Model Market Industry is significantly influenced by the increasing demand for personalized medicine. Surgeons and medical professionals are recognizing the value of customized surgical models that reflect the unique anatomy of individual patients. This trend is leading to enhanced surgical precision and improved patient outcomes. As healthcare systems worldwide shift towards personalized treatment plans, the adoption of 3D printed models is expected to rise. By 2035, the market is anticipated to expand to 10.2 USD Billion, reflecting the growing emphasis on tailored healthcare solutions that cater to specific patient needs.

Technological Advancements in 3D Printing

The Global 3D Printed Surgical Model Market Industry is experiencing rapid growth due to continuous technological advancements in 3D printing techniques. Innovations such as bioprinting and multi-material printing are enhancing the precision and functionality of surgical models. These advancements allow for the creation of highly detailed anatomical replicas that can be tailored to individual patient needs. As a result, healthcare providers are increasingly adopting these models for pre-surgical planning and education. The market is projected to reach 2.95 USD Billion in 2024, indicating a strong demand driven by improved technologies that facilitate better surgical outcomes.

Growing Applications in Various Surgical Fields

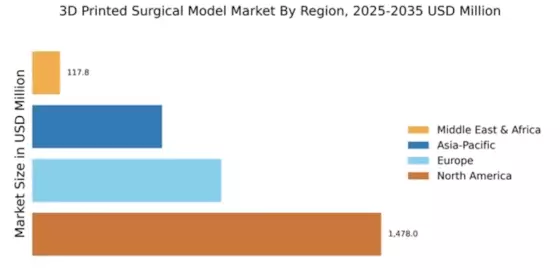

The Global 3D Printed Surgical Model Market Industry is characterized by its expanding applications across various surgical fields, including orthopedics, cardiology, and neurosurgery. Each specialty benefits from the ability to create specific models that replicate complex anatomical structures, thus enhancing surgical planning and execution. For instance, orthopedic surgeons can utilize 3D printed models to visualize bone deformities and plan corrective procedures. This versatility across disciplines is likely to drive market growth, as healthcare professionals increasingly recognize the advantages of using 3D printed models in diverse surgical contexts.

Increased Focus on Surgical Training and Education

The Global 3D Printed Surgical Model Market Industry is also driven by the heightened focus on surgical training and education. Medical institutions are increasingly utilizing 3D printed models to provide realistic training experiences for surgical residents and students. These models allow for hands-on practice in a controlled environment, thereby improving the skills and confidence of future surgeons. As educational institutions recognize the benefits of incorporating 3D printed models into their curricula, the demand for these resources is likely to rise. This trend supports the overall growth of the market, as more institutions seek innovative training solutions.