Technological Advancements

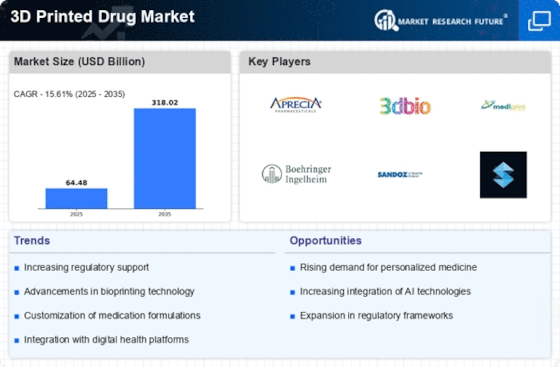

The 3D Printed Drug Market is experiencing rapid technological advancements that enhance the precision and efficiency of drug manufacturing. Innovations in 3D printing technologies, such as bioprinting and multi-material printing, allow for the creation of complex drug formulations tailored to individual patient needs. This customization capability is expected to drive market growth, as it aligns with the increasing demand for personalized medicine. According to recent estimates, the market for 3D printed pharmaceuticals is projected to reach USD 6.5 billion by 2027, reflecting a compound annual growth rate of approximately 20%. These advancements not only improve patient outcomes but also streamline production processes, reducing costs and time-to-market for new drugs.

Regulatory Support and Frameworks

The 3D Printed Drug Market is benefiting from evolving regulatory support and frameworks that facilitate the approval and commercialization of 3D printed pharmaceuticals. Regulatory bodies are increasingly recognizing the potential of 3D printing to revolutionize drug development and are establishing guidelines to ensure safety and efficacy. This supportive environment encourages innovation and investment in the sector. For instance, the FDA has issued guidance on the use of 3D printing in drug manufacturing, which is likely to expedite the approval process for new products. As regulatory clarity improves, more companies are expected to enter the market, contributing to its growth and diversification.

Cost Efficiency in Drug Production

Cost efficiency is a pivotal driver in the 3D Printed Drug Market, as traditional drug manufacturing processes often involve high overhead costs and lengthy production times. 3D printing technology offers a more streamlined approach, enabling on-demand production and reducing waste associated with excess inventory. This efficiency not only lowers production costs but also allows for rapid prototyping and iteration of drug formulations. As pharmaceutical companies seek to optimize their operations, the adoption of 3D printing is expected to rise. Market analyses indicate that companies utilizing 3D printing can reduce their production costs by up to 30%, making this technology an attractive option for both established firms and startups in the pharmaceutical sector.

Rising Demand for Personalized Medicine

The 3D Printed Drug Market is significantly influenced by the rising demand for personalized medicine. Patients increasingly seek treatments that are tailored to their unique genetic profiles and health conditions. 3D printing technology facilitates the production of customized drug dosages and delivery systems, which can enhance therapeutic efficacy and minimize side effects. This trend is supported by a growing body of research indicating that personalized treatments can lead to better patient adherence and outcomes. As healthcare systems shift towards more individualized approaches, the 3D printed drug market is likely to expand, with projections suggesting a market size of USD 5 billion by 2026, driven by innovations in drug formulation and delivery.

Increased Investment in Research and Development

Investment in research and development is a crucial driver for the 3D Printed Drug Market, as pharmaceutical companies and research institutions explore the potential of 3D printing technologies. Increased funding is directed towards developing novel drug formulations and delivery systems that leverage 3D printing capabilities. This investment is not only fostering innovation but also enhancing collaboration between academia and industry, leading to breakthroughs in drug design and manufacturing. Reports indicate that R&D spending in the pharmaceutical sector is projected to exceed USD 200 billion annually by 2026, with a significant portion allocated to exploring advanced manufacturing techniques like 3D printing. This trend is likely to propel the market forward, as new discoveries translate into commercially viable products.