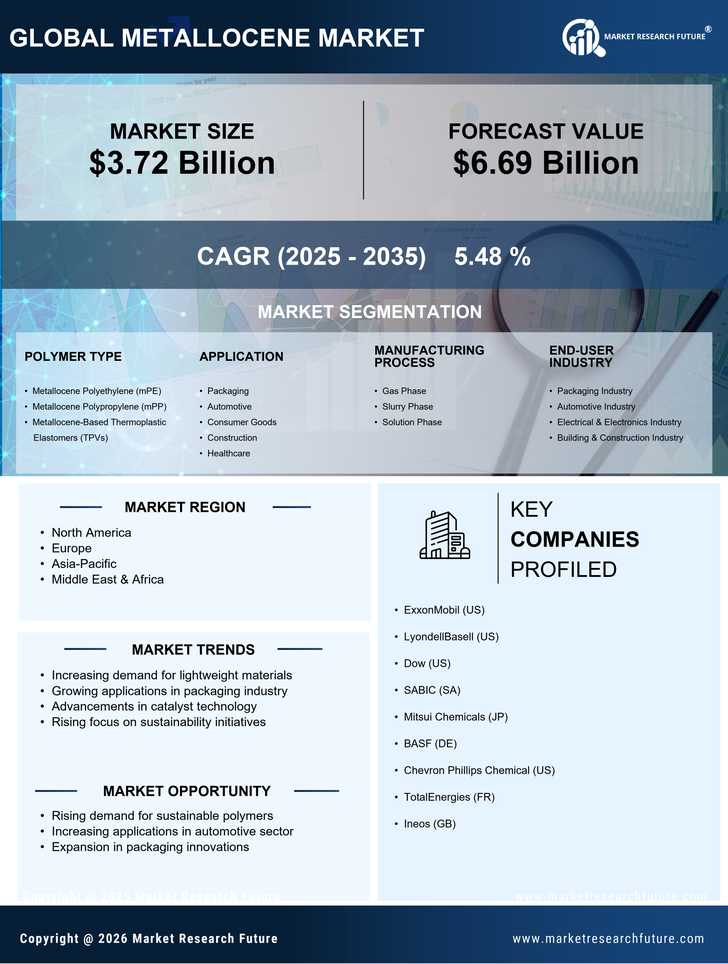

Expansion of the Packaging Sector

The expansion of the packaging sector is a critical driver for the Metallocene Market. With the rise in e-commerce and consumer goods, the demand for innovative packaging solutions has surged. Metallocene Market-based polymers are favored for their excellent barrier properties, flexibility, and durability, making them ideal for food and beverage packaging. The packaging industry is expected to witness a growth rate of around 5% annually, further propelling the demand for metallocene materials. This trend indicates that the Metallocene Market will likely see increased investments and collaborations aimed at developing sustainable and efficient packaging solutions.

Growth in Automotive Applications

The growth in automotive applications is a significant driver for the Metallocene Market. As the automotive sector increasingly focuses on lightweight materials to enhance fuel efficiency and reduce emissions, metallocene polymers are gaining traction. These materials offer superior performance characteristics, such as impact resistance and thermal stability, making them suitable for various automotive components. The automotive industry is projected to grow at a rate of approximately 4% annually, which will likely lead to increased demand for metallocene-based solutions. Consequently, the Metallocene Market is expected to capitalize on this trend, providing innovative materials that meet the evolving needs of automotive manufacturers.

Innovations in Catalyst Technology

Innovations in catalyst technology are significantly influencing the Metallocene Market. The development of advanced metallocene catalysts has led to the production of polymers with tailored properties, enabling manufacturers to meet specific performance requirements. These innovations not only enhance the efficiency of polymer production but also expand the range of applications for metallocene-based materials. For instance, the introduction of single-site catalysts has improved the control over polymer architecture, resulting in materials with enhanced clarity and strength. As a result, the Metallocene Market is poised for growth, with an increasing number of companies investing in research and development to leverage these technological advancements.

Rising Demand for High-Performance Polymers

The Metallocene Market is experiencing a notable increase in demand for high-performance polymers, which are utilized in various applications such as automotive, packaging, and consumer goods. These polymers, characterized by their superior mechanical properties and thermal stability, are increasingly preferred over traditional polymers. The market for high-performance polymers is projected to grow at a compound annual growth rate of approximately 6% over the next few years. This growth is driven by the need for lightweight materials that enhance fuel efficiency in vehicles and reduce overall production costs. As industries seek to improve product performance and sustainability, the Metallocene Market is likely to benefit from this trend, positioning itself as a key player in the supply of advanced polymer solutions.

Regulatory Support for Sustainable Materials

Regulatory support for sustainable materials is becoming increasingly prominent, positively impacting the Metallocene Market. Governments and regulatory bodies are implementing stringent regulations aimed at reducing plastic waste and promoting the use of recyclable materials. Metallocene Market polymers, known for their recyclability and lower environmental impact, are well-positioned to meet these regulatory demands. As industries adapt to these changes, the Metallocene Market is likely to experience a surge in demand for eco-friendly alternatives. This shift not only aligns with global sustainability goals but also encourages innovation within the industry, fostering the development of new metallocene-based products that comply with environmental standards.