Focus on Energy Efficiency

In the Thermal Spray Powder Market, there is a growing emphasis on energy efficiency and sustainability. Industries are increasingly adopting thermal spray coatings as a means to improve the energy efficiency of machinery and equipment. By applying thermal spray coatings, companies can reduce friction and wear, leading to lower energy consumption and enhanced operational efficiency. This trend is particularly evident in sectors such as manufacturing and power generation, where energy costs are a significant concern. The potential for thermal spray technologies to contribute to energy savings is prompting more organizations to explore these solutions, thereby driving market growth. As energy regulations become more stringent, the adoption of thermal spray coatings is likely to increase, aligning with broader sustainability goals.

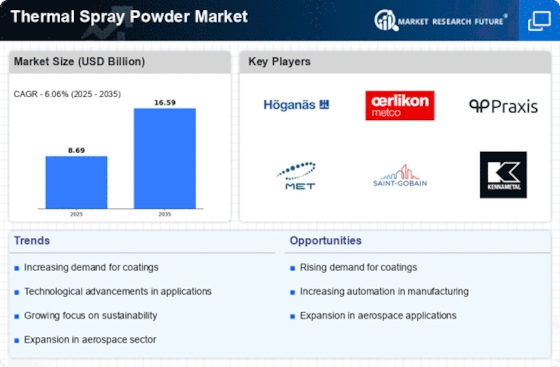

Rising Demand for Coatings

The Thermal Spray Powder Market is experiencing a notable increase in demand for protective coatings across various sectors. Industries such as aerospace, automotive, and energy are increasingly utilizing thermal spray coatings to enhance the durability and performance of components. This trend is driven by the need for materials that can withstand extreme conditions, such as high temperatures and corrosive environments. According to recent data, the thermal spray coatings segment is projected to grow at a compound annual growth rate of approximately 6% over the next few years. This growth is indicative of the broader acceptance of thermal spray technologies, which are recognized for their ability to extend the lifespan of critical components, thereby reducing maintenance costs and downtime.

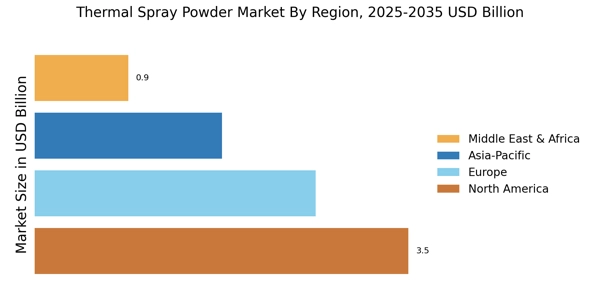

Growth in Aerospace and Defense Sectors

The Thermal Spray Powder Market is significantly influenced by the expansion of the aerospace and defense sectors. These industries require high-performance materials that can endure extreme operational conditions, making thermal spray coatings an ideal choice. The increasing production of aircraft and military equipment is driving the demand for thermal spray powders, which are utilized for coating turbine blades, landing gear, and other critical components. Recent statistics indicate that the aerospace sector alone is expected to witness a growth rate of around 5% annually, further propelling the need for advanced thermal spray solutions. This trend underscores the importance of thermal spray technologies in enhancing the reliability and safety of aerospace applications.

Advancements in Thermal Spray Technologies

Technological innovations within the Thermal Spray Powder Market are playing a pivotal role in shaping market dynamics. The development of advanced thermal spray techniques, such as high-velocity oxygen fuel (HVOF) and cold spray processes, is enhancing the efficiency and effectiveness of coating applications. These advancements allow for better adhesion, reduced porosity, and improved surface finish, which are crucial for high-performance applications. Furthermore, the integration of automation and robotics in thermal spray processes is streamlining production, thereby increasing throughput and reducing labor costs. As a result, manufacturers are likely to invest more in these technologies, anticipating a shift towards more sophisticated thermal spray solutions that meet the evolving demands of various industries.

Increasing Investment in Research and Development

The Thermal Spray Powder Market is witnessing a surge in investment directed towards research and development activities. Companies are recognizing the need to innovate and improve their thermal spray technologies to stay competitive in a rapidly evolving market. This investment is aimed at developing new powder materials, enhancing coating properties, and exploring novel applications for thermal spray solutions. As a result, there is a growing pipeline of advanced thermal spray products that are expected to enter the market in the coming years. This focus on R&D not only fosters innovation but also helps in addressing specific industry challenges, thereby expanding the potential applications of thermal spray technologies across various sectors.

.png)