Sustainability Initiatives

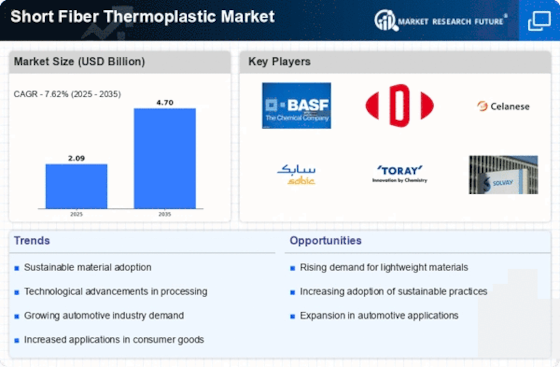

The increasing emphasis on sustainability initiatives is a pivotal driver for the Short Fiber Thermoplastic Market. As industries strive to reduce their carbon footprints, the demand for eco-friendly materials has surged. Short fiber thermoplastics, known for their recyclability and lower environmental impact, align well with these sustainability goals. In 2025, the market for sustainable materials is projected to reach substantial figures, indicating a shift towards greener alternatives. This trend is particularly pronounced in sectors such as automotive and consumer goods, where manufacturers are actively seeking materials that not only meet performance standards but also adhere to environmental regulations. Consequently, the Short Fiber Thermoplastic Market is likely to experience robust growth as companies prioritize sustainable practices.

Growing Demand in Automotive Sector

The automotive sector's growing demand for lightweight materials is a key driver for the Short Fiber Thermoplastic Market. As manufacturers seek to enhance fuel efficiency and reduce emissions, the adoption of short fiber thermoplastics has become increasingly prevalent. These materials offer a favorable strength-to-weight ratio, making them ideal for various automotive components, including interior parts and structural elements. In 2025, the automotive industry is expected to account for a significant share of the short fiber thermoplastic market, reflecting a broader trend towards lightweighting in vehicle design. This shift not only meets regulatory requirements but also aligns with consumer preferences for more efficient vehicles. Consequently, the Short Fiber Thermoplastic Market is likely to thrive as automotive manufacturers continue to prioritize innovative materials.

Rising Applications in Consumer Goods

The rising applications of short fiber thermoplastics in consumer goods represent a notable driver for the Short Fiber Thermoplastic Market. As consumer preferences evolve towards durable and lightweight products, manufacturers are increasingly incorporating these materials into their designs. Short fiber thermoplastics are utilized in a variety of consumer goods, including electronics, household items, and sporting equipment, due to their excellent mechanical properties and aesthetic versatility. By 2025, the market for consumer goods utilizing short fiber thermoplastics is anticipated to expand, driven by the demand for innovative and sustainable products. This trend indicates a shift in consumer behavior towards products that not only perform well but also contribute to environmental sustainability. Thus, the Short Fiber Thermoplastic Market is expected to benefit from this growing consumer inclination.

Technological Advancements in Processing

Technological advancements in processing techniques are significantly influencing the Short Fiber Thermoplastic Market. Innovations such as improved injection molding and extrusion processes have enhanced the efficiency and quality of short fiber thermoplastic products. These advancements allow for better fiber dispersion and improved mechanical properties, which are crucial for applications in various sectors, including automotive and aerospace. As of 2025, the market is witnessing a shift towards more sophisticated processing technologies that enable manufacturers to produce lightweight and high-performance components. This trend not only boosts production efficiency but also reduces waste, further appealing to manufacturers focused on sustainability. Thus, the Short Fiber Thermoplastic Market is poised for growth driven by these technological improvements.

Increased Investment in Research and Development

Increased investment in research and development (R&D) is a crucial driver for the Short Fiber Thermoplastic Market. As companies seek to innovate and enhance the performance of short fiber thermoplastics, R&D efforts are intensifying. This investment focuses on developing new formulations and processing techniques that improve the properties of these materials, such as impact resistance and thermal stability. By 2025, the market is likely to see a surge in new product offerings resulting from these R&D initiatives, which could lead to expanded applications across various industries, including construction and electronics. Furthermore, collaboration between academic institutions and industry players is fostering innovation, thereby propelling the Short Fiber Thermoplastic Market forward. This emphasis on R&D is expected to yield significant advancements, enhancing the competitive landscape.