Rising Demand for Efficiency

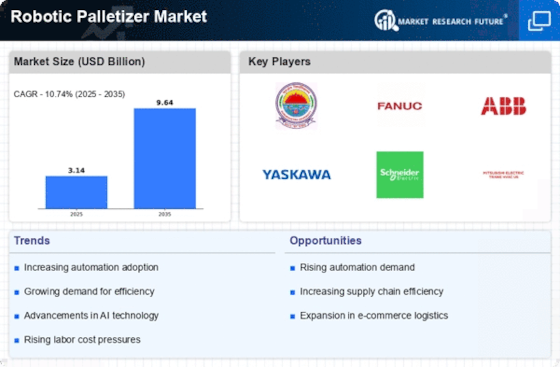

The Robotic Palletizer Market is experiencing a notable surge in demand for efficiency across various sectors. Companies are increasingly seeking to optimize their operations, reduce labor costs, and enhance productivity. This trend is particularly evident in industries such as food and beverage, pharmaceuticals, and consumer goods, where the need for rapid and accurate palletizing solutions is paramount. According to recent data, the market for robotic palletizers is projected to grow at a compound annual growth rate of approximately 10% over the next five years. This growth is driven by the necessity for streamlined processes and the ability to handle diverse product types, which robotic palletizers can effectively manage. As businesses strive to remain competitive, the adoption of robotic palletizers is likely to become a standard practice, further propelling the market forward.

Technological Advancements in Robotics

The Robotic Palletizer Market is witnessing rapid technological advancements that are reshaping the landscape of automation. Innovations in artificial intelligence, machine learning, and sensor technologies are enhancing the capabilities of robotic palletizers, making them more adaptable and efficient. These advancements enable robotic systems to perform complex tasks with greater precision and speed, which is crucial for industries that require high throughput. Furthermore, the introduction of collaborative robots, or cobots, is allowing for safer interactions between human workers and machines, thereby expanding the potential applications of robotic palletizers. As these technologies continue to evolve, they are likely to attract more investments and drive the growth of the market, as companies seek to leverage cutting-edge solutions to improve their operational efficiency.

Labor Shortages and Workforce Challenges

The Robotic Palletizer Market is significantly influenced by ongoing labor shortages and workforce challenges. Many sectors are grappling with difficulties in finding skilled labor, which has led to increased operational costs and inefficiencies. In response, companies are turning to robotic palletizers as a viable solution to mitigate these challenges. By automating the palletizing process, businesses can not only alleviate the pressure of labor shortages but also ensure consistent output quality. The integration of robotic systems allows for a more reliable and efficient workflow, which is essential in maintaining production schedules. As labor markets continue to tighten, the reliance on robotic palletizers is expected to grow, thereby driving market expansion and innovation in automation technologies.

Customization and Versatility in Production

The Robotic Palletizer Market is characterized by a rising demand for customization and versatility in production processes. As consumer preferences evolve, manufacturers are increasingly required to produce a wider variety of products in smaller batches. Robotic palletizers are uniquely positioned to address this need, as they can be easily reprogrammed and adapted to handle different product types and packaging configurations. This flexibility allows companies to respond swiftly to market changes and consumer demands, thereby enhancing their competitive edge. The ability to customize palletizing solutions is becoming a key differentiator for businesses, leading to increased investments in robotic technologies. As the market continues to evolve, the emphasis on customization is expected to drive further growth in the robotic palletizer sector.

Sustainability and Environmental Considerations

The Robotic Palletizer Market is increasingly aligning with sustainability and environmental considerations. As companies become more aware of their ecological footprint, there is a growing emphasis on adopting practices that minimize waste and energy consumption. Robotic palletizers contribute to these sustainability goals by optimizing packaging processes and reducing material waste. Additionally, the energy efficiency of modern robotic systems is improving, which aligns with corporate sustainability initiatives. Many organizations are now prioritizing investments in automation technologies that not only enhance productivity but also support their environmental objectives. This shift towards sustainable practices is likely to drive demand for robotic palletizers, as businesses seek solutions that align with their commitment to environmental stewardship.