North America : Market Leader in Services

North America is poised to maintain its leadership in the Refinery Boiler Maintenance and Repair Services Market, holding a significant market share of 3.25 billion. The region's growth is driven by stringent regulatory standards, increasing demand for energy efficiency, and the need for modernization of aging infrastructure. The focus on reducing emissions and enhancing operational efficiency further propels market expansion.

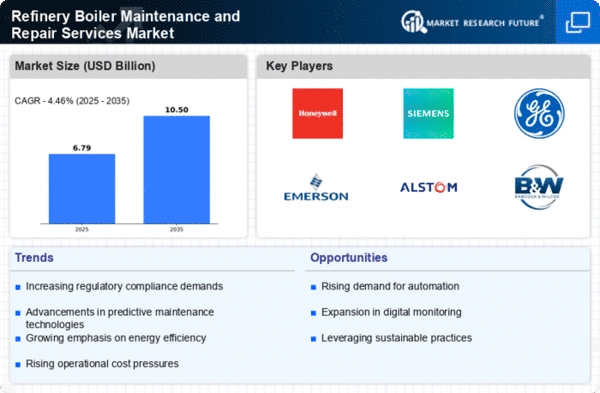

The United States stands out as the leading country, with major players like Honeywell, General Electric, and Emerson Electric dominating the landscape. The competitive environment is characterized by continuous innovation and strategic partnerships among key players. The presence of advanced technologies and a skilled workforce enhances service delivery, ensuring that North America remains at the forefront of the industry.

Europe : Emerging Regulatory Frameworks

Europe's Refinery Boiler Maintenance and Repair Services Market is valued at 1.8 billion, reflecting a growing emphasis on sustainability and compliance with environmental regulations. The region is witnessing increased investments in renewable energy and retrofitting existing facilities to meet new standards. Regulatory frameworks are evolving, pushing for enhanced safety and efficiency in refinery operations, which is a key driver for market growth.

Leading countries such as Germany, France, and the UK are at the forefront of this transformation, with companies like Siemens and Alstom playing pivotal roles. The competitive landscape is marked by a mix of established firms and emerging players, all striving to innovate and adapt to regulatory demands. The focus on reducing carbon footprints and improving energy efficiency is reshaping service offerings in the region.

Asia-Pacific : Rapid Industrialization and Growth

The Asia-Pacific region, with a market size of 1.5 billion, is experiencing rapid growth in the Refinery Boiler Maintenance and Repair Services Market. This growth is fueled by increasing industrialization, urbanization, and rising energy demands. Countries are investing heavily in refining capacities and modernizing existing facilities to enhance efficiency and comply with environmental regulations, driving demand for maintenance and repair services.

China and India are the leading countries in this region, with significant investments in refining infrastructure. The competitive landscape features both local and international players, including Mitsubishi Hitachi Power Systems. The market is characterized by a focus on cost-effective solutions and technological advancements, as companies strive to meet the growing demand for reliable and efficient services.

Middle East and Africa : Resource-Rich Opportunities

The Middle East and Africa region, valued at 0.95 billion, presents unique opportunities in the Refinery Boiler Maintenance and Repair Services Market. The growth is primarily driven by the region's rich natural resources and the increasing need for efficient energy production. Governments are investing in refining capabilities to meet both domestic and international energy demands, which is propelling the market forward.

Countries like Saudi Arabia and South Africa are leading the charge, with significant investments in refinery upgrades and maintenance services. The competitive landscape is evolving, with both local firms and international players seeking to establish a foothold. The focus on enhancing operational efficiency and sustainability is shaping service offerings in this resource-rich region.