North America : Market Leader in Refinery Maintenance

North America is poised to maintain its leadership in the Crude Oil Refinery Maintenance Market, holding a significant market share of 75.0 in 2024. The region's growth is driven by increasing demand for refined products, stringent environmental regulations, and the need for technological advancements in maintenance practices. The regulatory landscape encourages investments in sustainable practices, further propelling market growth.

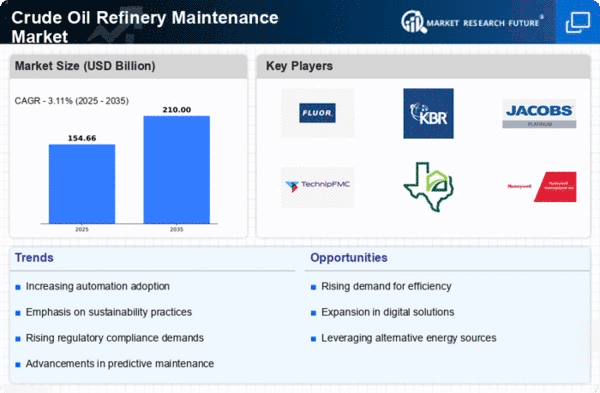

The United States stands out as the leading country in this sector, with major players like Fluor Corporation, KBR, and Jacobs Engineering Group driving innovation and efficiency. The competitive landscape is characterized by a mix of established firms and emerging players, all vying for market share. The presence of key players ensures a robust supply chain and service delivery, enhancing the overall market dynamics.

Europe : Emerging Market with Growth Potential

Europe, with a market size of 35.0, is witnessing a revitalization in the Crude Oil Refinery Maintenance Market. The region's growth is fueled by the increasing focus on energy efficiency, regulatory compliance, and the transition towards cleaner energy sources. Governments are implementing policies that promote sustainable practices, which are expected to drive demand for maintenance services in the coming years.

Leading countries such as Germany, France, and the UK are at the forefront of this transformation, with key players like TechnipFMC and Wood Group actively participating in the market. The competitive landscape is evolving, with a mix of local and international firms competing for contracts. The presence of established companies ensures a high standard of service and innovation, positioning Europe as a significant player in the global market.

Asia-Pacific : Rapidly Growing Market Dynamics

Asia-Pacific is emerging as a rapidly growing market in the Crude Oil Refinery Maintenance sector, with a market size of 30.0. The region's growth is driven by increasing industrialization, urbanization, and rising energy demands. Countries are investing heavily in refining capacities, leading to a surge in maintenance requirements. Regulatory frameworks are also evolving to ensure compliance with environmental standards, further boosting market demand.

China and India are the leading countries in this region, with significant investments in refinery upgrades and maintenance services. The competitive landscape features both local and international players, including Honeywell and McDermott International, who are leveraging technology to enhance service delivery. This dynamic environment is expected to foster innovation and improve operational efficiencies across the sector.

Middle East and Africa : Resource-Rich Market Opportunities

The Middle East and Africa region, with a market size of 10.0, presents unique opportunities in the Crude Oil Refinery Maintenance Market. The region's growth is primarily driven by its vast oil reserves and the need for efficient maintenance practices to maximize output. Governments are increasingly recognizing the importance of maintaining refinery infrastructure to ensure operational efficiency and compliance with international standards.

Countries like Saudi Arabia and the UAE are leading the charge, with significant investments in refining capabilities and maintenance services. The competitive landscape is characterized by a mix of local firms and international players, including Saipem and Babcock International Group, who are well-positioned to capitalize on the region's growth potential. This combination of resources and expertise is expected to drive the market forward.