Rising Demand for Packaging Solutions

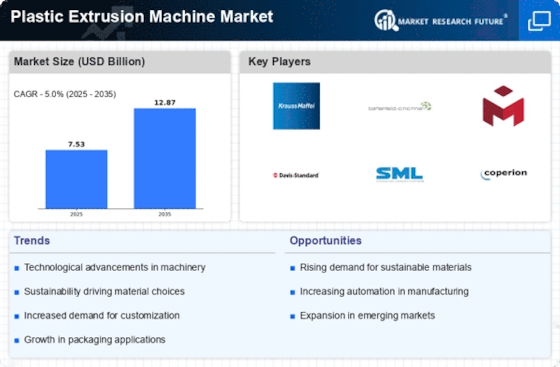

The increasing demand for packaging solutions across various industries is a primary driver for the Plastic Extrusion Machine Industry. As consumer preferences shift towards convenience and sustainability, manufacturers are compelled to innovate packaging materials. The market for flexible packaging is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 4% in the coming years. This trend necessitates advanced plastic extrusion technologies that can produce lightweight, durable, and recyclable materials. Consequently, companies are investing in state-of-the-art extrusion machines to meet these evolving requirements, thereby propelling the growth of the Plastic Extrusion Machine Market.

Increased Focus on Recycling and Sustainability

The heightened focus on recycling and sustainability is a crucial driver for the Plastic Extrusion Machine Industry. As environmental concerns gain prominence, industries are increasingly adopting sustainable practices, including the use of recycled plastics. The market for recycled plastic products is expected to expand, with projections indicating a growth rate of around 6% annually. This shift necessitates the development of extrusion machines capable of processing recycled materials efficiently. Manufacturers are responding by investing in technologies that facilitate the recycling of plastics, thereby aligning with sustainability goals and driving the evolution of the Plastic Extrusion Machine, especially as demand for advanced plastic extruder machine continues to rise.

Technological Innovations in Extrusion Processes

Technological innovations in extrusion processes are significantly shaping the Plastic Extrusion Machine. The advent of Industry 4.0 and automation technologies has led to the development of smarter, more efficient extrusion machines. These innovations enhance production capabilities, reduce waste management, and improve product quality. For instance, the integration of IoT and AI in extrusion processes allows for real-time monitoring and predictive maintenance, which can reduce downtime by up to 20%. As manufacturers strive for operational excellence, the demand for technologically advanced extrusion machines is likely to surge, further driving the growth of the Plastic Extrusion Machine.

Expanding Automotive Sector and Lightweight Materials

The expanding automotive sector is a significant driver for the Plastic Extrusion Machine, particularly with the growing emphasis on lightweight materials. As automotive manufacturers seek to enhance fuel efficiency and reduce emissions, the demand for lightweight plastic components is on the rise. The automotive plastics market is projected to grow at a rate of approximately 7% annually, which directly influences the need for advanced extrusion technologies. This trend compels manufacturers to invest in high-performance extrusion machines that can produce complex shapes and designs, thereby supporting the evolving requirements of the automotive industry and propelling the Plastic Extrusion Machine.

Growth in Construction and Infrastructure Development

The ongoing expansion in construction and infrastructure development is a notable driver for the Plastic Extrusion Machine Market. With urbanization trends accelerating, there is a heightened demand for plastic components in construction applications, such as pipes, profiles, and sheets. The construction sector is expected to witness a growth rate of approximately 5% annually, which directly influences the need for efficient plastic extrusion processes. As builders and contractors seek to utilize lightweight and cost-effective materials, the adoption of advanced extrusion machines becomes essential. This trend underscores the pivotal role of the Plastic Extrusion Machine in supporting the construction landscape.