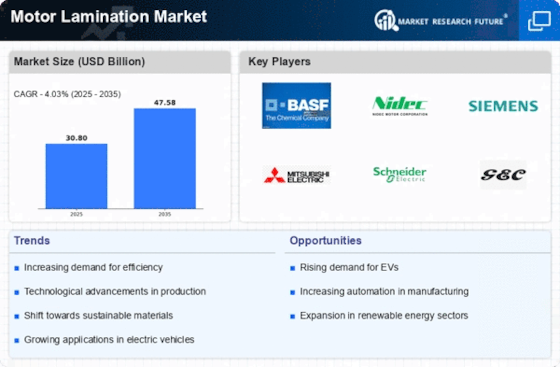

Growth of Renewable Energy Sector

The expansion of the renewable energy sector is significantly influencing the Motor Lamination Market. As the world increasingly turns to renewable energy sources, the demand for efficient electric motors in wind turbines and solar energy systems is on the rise. In 2025, the renewable energy market is anticipated to grow, with wind and solar power installations requiring high-quality motor laminations for optimal performance. This trend suggests that manufacturers in the Motor Lamination Market will need to adapt their offerings to cater to the specific requirements of renewable energy applications, potentially leading to new product developments.

Rising Demand for Electric Vehicles

The increasing demand for electric vehicles (EVs) is a primary driver for the Motor Lamination Market. As governments and consumers alike prioritize sustainability, the shift towards EVs necessitates the use of efficient motor laminations. In 2025, the EV market is projected to grow significantly, with estimates suggesting that electric vehicles could account for over 30% of total vehicle sales. This surge in EV production directly correlates with the need for high-performance motor laminations, which enhance the efficiency and performance of electric motors. Consequently, manufacturers in the Motor Lamination Market are likely to invest in advanced materials and technologies to meet this growing demand.

Increased Focus on Energy Efficiency

The Motor Lamination Industry. As industries strive to reduce energy consumption and lower operational costs, the demand for energy-efficient motors is escalating. Motor laminations play a crucial role in enhancing the efficiency of electric motors, which is vital for various applications, including industrial machinery and consumer electronics. In 2025, it is expected that regulatory frameworks will increasingly mandate energy efficiency standards, compelling manufacturers to innovate and improve their motor lamination products to comply with these regulations, thereby expanding their market reach.

Advancements in Manufacturing Techniques

Innovations in manufacturing techniques are transforming the Motor Lamination Market. Techniques such as laser cutting and advanced stamping are enhancing the precision and efficiency of motor lamination production. These advancements not only reduce waste but also improve the overall quality of the laminations. In 2025, the adoption of automated manufacturing processes is expected to rise, leading to increased production capacities and reduced lead times. This shift towards more efficient manufacturing methods is likely to attract new players into the Motor Lamination Market, further stimulating competition and innovation.

Technological Integration in Manufacturing Processes

The integration of advanced technologies such as IoT and AI in manufacturing processes is reshaping the Motor Lamination Market. These technologies enable real-time monitoring and predictive maintenance, which can enhance production efficiency and reduce downtime. In 2025, manufacturers are likely to leverage these technologies to optimize their operations, leading to improved product quality and reduced costs. This technological shift may also facilitate the development of smart motor laminations that can adapt to varying operational conditions, thus broadening the application scope within the Motor Lamination Market.