Integration of AI and Automation

The integration of artificial intelligence (AI) and automation technologies is transforming the digital inspection market in Japan. Companies are increasingly leveraging AI-driven solutions to enhance inspection accuracy and efficiency. By automating inspection processes, organizations can significantly reduce human error and improve throughput. In 2025, it is estimated that AI-enabled inspection systems will account for over 30% of the market share, indicating a strong shift towards automation. This trend not only streamlines operations but also allows for real-time data analysis, enabling quicker decision-making. As businesses seek to optimize their inspection processes, the adoption of AI and automation is likely to play a crucial role in shaping the future of the digital inspection market.

Growing Focus on Safety Standards

In Japan, there is an increasing emphasis on safety standards across various sectors, which is significantly impacting the digital inspection market. Industries such as construction, manufacturing, and food processing are under pressure to comply with stringent safety regulations. This focus on safety is driving the demand for advanced inspection technologies that can ensure compliance and mitigate risks. The market is expected to witness a growth rate of around 12% in 2025, as companies invest in digital inspection solutions to meet regulatory requirements. By adopting these technologies, organizations can enhance their safety protocols, thereby fostering a culture of safety and reliability within their operations. This trend underscores the critical role of digital inspection in maintaining safety standards.

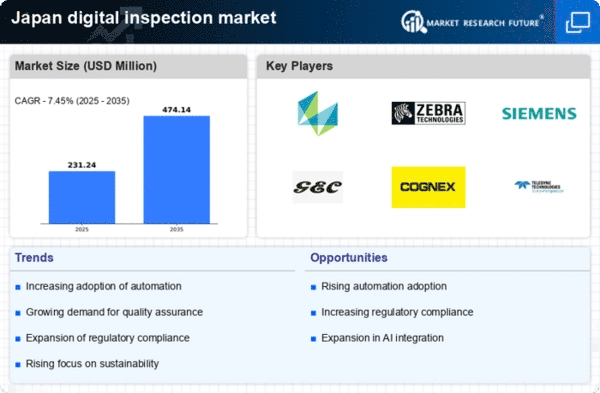

Rising Demand for Quality Assurance

Japan is experiencing a notable surge in demand for quality assurance across various industries. This trend is driven by the increasing need for precision and reliability in manufacturing processes. As companies strive to enhance product quality, the adoption of digital inspection technologies becomes essential. In 2025, the market is projected to grow by approximately 15%, reflecting the industry's commitment to maintaining high standards. The integration of advanced inspection systems not only improves product quality but also reduces operational costs, thereby making it a vital component of the digital inspection market. Furthermore, the emphasis on quality assurance is likely to lead to increased investments in innovative inspection solutions, further propelling market growth.

Increased Investment in Infrastructure

Japan's ongoing investment in infrastructure development is creating a favorable environment for the digital inspection market. As the government allocates substantial funds towards upgrading transportation, utilities, and public facilities, the need for effective inspection solutions becomes paramount. The digital inspection market is projected to benefit from this trend, with an anticipated growth of 10% in 2025. Enhanced infrastructure projects require rigorous inspection processes to ensure quality and safety, thereby driving the adoption of digital inspection technologies. Furthermore, the integration of these technologies into infrastructure projects can lead to improved project timelines and cost efficiencies, making them indispensable in the current market landscape.

Shift Towards Remote Inspection Solutions

Japan is witnessing a shift towards remote inspection solutions, driven by advancements in communication technologies. As businesses seek to minimize operational disruptions and enhance efficiency, remote inspection methods are becoming increasingly popular. This trend is particularly relevant in sectors such as manufacturing and construction, where on-site inspections can be challenging. By utilizing remote inspection technologies, companies can conduct inspections without the need for physical presence, thereby saving time and resources. In 2025, it is projected that remote inspection solutions will capture a significant share of the market, potentially exceeding 20%. This shift not only reflects the evolving nature of inspection processes but also highlights the importance of adaptability in the digital inspection market.