Cost Efficiency

Cost efficiency is a pivotal factor influencing the Digital Inspection Market. Organizations are increasingly seeking ways to reduce operational costs while maintaining high standards of quality and safety. Digital inspection technologies offer a solution by minimizing the need for manual inspections and reducing the time required for assessments. This efficiency translates into lower labor costs and faster turnaround times, which are crucial in competitive markets. Furthermore, the ability to detect issues early can prevent costly rework and product recalls. As businesses strive to optimize their operations, the demand for cost-effective digital inspection solutions is likely to rise, driving market growth.

Regulatory Compliance

Regulatory compliance is a critical driver in the Digital Inspection Market, as industries face increasing scrutiny from regulatory bodies. Companies are required to adhere to stringent safety and quality standards, which necessitates the implementation of effective inspection processes. Digital inspection solutions provide the necessary tools to ensure compliance with regulations, thereby reducing the risk of penalties and enhancing operational integrity. The market is witnessing a shift towards automated compliance reporting, which streamlines the documentation process and improves transparency. This trend is expected to contribute to a significant portion of the market's growth, as organizations prioritize compliance in their operational strategies.

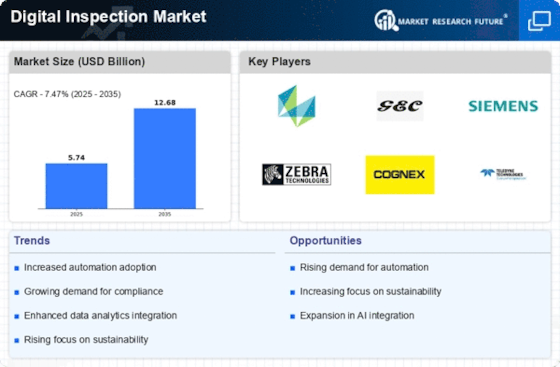

Technological Advancements

The Digital Inspection Market is experiencing a surge in technological advancements that enhance inspection processes. Innovations such as artificial intelligence, machine learning, and advanced imaging techniques are transforming traditional inspection methods. These technologies enable faster and more accurate assessments, reducing human error and increasing efficiency. For instance, the integration of AI algorithms in inspection tools allows for predictive maintenance, which can potentially save companies significant costs. The market for digital inspection technologies is projected to grow at a compound annual growth rate of approximately 10% over the next five years, indicating a robust demand for these advanced solutions.

Integration with Industry 4.0

The integration of digital inspection technologies with Industry 4.0 principles is significantly shaping the Digital Inspection Market. As industries embrace smart manufacturing and the Internet of Things, the need for interconnected inspection systems becomes paramount. Digital inspection tools that can seamlessly integrate with other smart technologies enable real-time monitoring and data analysis, enhancing decision-making processes. This integration not only improves operational efficiency but also allows for more agile responses to market demands. The trend towards Industry 4.0 is expected to propel the adoption of digital inspection solutions, as companies seek to leverage data-driven insights for continuous improvement.

Rising Demand for Quality Assurance

The rising demand for quality assurance across various sectors is propelling the Digital Inspection Market forward. As consumers become more discerning, companies are compelled to ensure that their products meet high-quality standards. Digital inspection technologies facilitate rigorous quality checks, enabling businesses to identify defects early in the production process. This proactive approach not only enhances product reliability but also fosters customer trust. Industries such as manufacturing and pharmaceuticals are particularly focused on quality assurance, driving the adoption of digital inspection solutions. The market is expected to see a notable increase in investments aimed at enhancing quality control measures, further solidifying the role of digital inspection.