Rising Demand for Quality Assurance

The digital inspection market in South Korea is experiencing a notable surge in demand for quality assurance across various industries. This trend is driven by the increasing need for compliance with stringent quality standards, particularly in manufacturing and construction sectors. Companies are investing in digital inspection technologies to enhance product reliability and safety, thereby reducing the risk of defects. In 2025, the market is projected to reach approximately $1.5 billion, reflecting a growth rate of around 12% annually. This growth is indicative of a broader shift towards adopting advanced inspection methods that ensure high-quality outputs, ultimately fostering consumer trust and satisfaction.

Emphasis on Safety and Risk Management

Safety and risk management are paramount concerns in various sectors, driving the digital inspection market in South Korea. Industries such as construction, energy, and transportation are increasingly adopting digital inspection solutions to mitigate risks associated with equipment failure and safety hazards. The implementation of these technologies is expected to reduce incident rates significantly, fostering a safer working environment. By 2025, the digital inspection market is anticipated to grow by 8%, as organizations prioritize safety measures and compliance with regulatory standards, ultimately enhancing operational resilience.

Increased Focus on Operational Efficiency

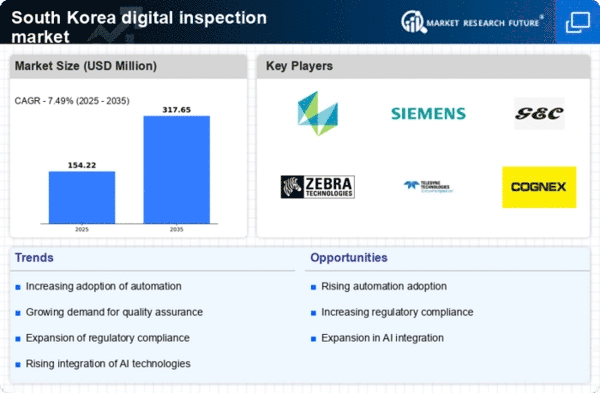

Operational efficiency remains a critical driver for the digital inspection market in South Korea. Organizations are increasingly recognizing the potential of digital inspection technologies to streamline processes and reduce operational costs. By integrating automated inspection systems, companies can minimize human error and enhance productivity. The digital inspection market is expected to witness a compound annual growth rate (CAGR) of 10% through 2025, as businesses seek to optimize their operations. This focus on efficiency not only improves the bottom line but also allows for quicker turnaround times, which is essential in a competitive landscape.

Growing Adoption of AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning into the digital inspection market is transforming traditional inspection methodologies. In South Korea, companies are leveraging these technologies to analyze vast amounts of data, enabling predictive maintenance and real-time decision-making. This shift is likely to enhance the accuracy and speed of inspections, reducing downtime and operational disruptions. As of 2025, it is estimated that AI-driven solutions could account for over 30% of the digital inspection market, reflecting a significant trend towards automation and intelligent systems that improve inspection outcomes.

Expansion of Smart Manufacturing Initiatives

Smart manufacturing initiatives are gaining traction in South Korea, significantly impacting the digital inspection market. The government's push towards Industry 4.0 is encouraging manufacturers to adopt advanced technologies, including digital inspection tools. This transition is expected to enhance production capabilities and ensure higher quality standards. By 2025, the digital inspection market is projected to benefit from a 15% increase in investments related to smart manufacturing technologies. This expansion not only supports economic growth but also positions South Korea as a leader in innovative manufacturing practices.