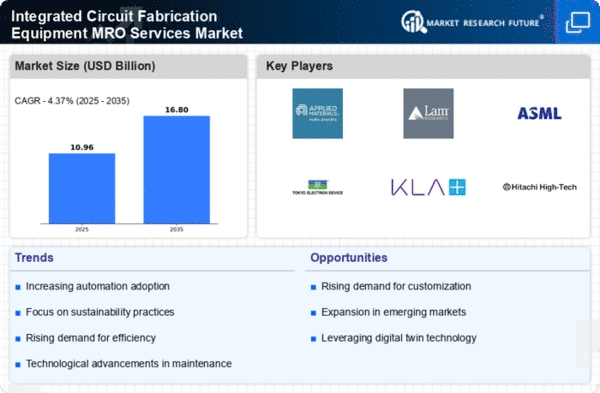

The Integrated Circuit Fabrication Equipment MRO Services Market is characterized by a dynamic competitive landscape, driven by technological advancements and increasing demand for semiconductor manufacturing. Key players such as Applied Materials (US), Lam Research (US), and ASML (NL) are at the forefront, each adopting distinct strategies to enhance their market positioning. Applied Materials (US) focuses on innovation in equipment efficiency and sustainability, while Lam Research (US) emphasizes partnerships to expand its service offerings. ASML (NL), known for its cutting-edge lithography systems, is investing heavily in R&D to maintain its technological edge. Collectively, these strategies foster a competitive environment that prioritizes technological leadership and operational excellence.In terms of business tactics, companies are increasingly localizing manufacturing to mitigate supply chain disruptions and optimize logistics. The market structure appears moderately fragmented, with a mix of established players and emerging firms. The collective influence of these key players shapes market dynamics, as they compete not only on price but also on service quality and technological capabilities.

In November KLA Corporation (US) announced a strategic partnership with a leading AI firm to enhance its process control solutions. This collaboration aims to integrate AI-driven analytics into KLA's existing product lines, potentially revolutionizing the way semiconductor manufacturers monitor and optimize their processes. Such a move underscores the growing importance of AI in the MRO services sector, as companies seek to leverage data for improved operational efficiency.

In October Tokyo Electron (JP) unveiled a new service model that focuses on predictive maintenance for its fabrication equipment. This initiative is designed to reduce downtime and enhance productivity for clients, reflecting a broader trend towards proactive service offerings in the industry. By adopting this model, Tokyo Electron (JP) positions itself as a leader in customer-centric solutions, which may significantly enhance client loyalty and retention.

In September Teradyne (US) expanded its global footprint by establishing a new service center in Southeast Asia. This strategic move is likely aimed at tapping into the rapidly growing semiconductor market in the region, which is becoming increasingly vital for global supply chains. By enhancing its local presence, Teradyne (US) can offer more responsive and tailored services to its clients, thereby strengthening its competitive position.

As of December current trends in the Integrated Circuit Fabrication Equipment MRO Services Market indicate a strong shift towards digitalization, sustainability, and AI integration. Strategic alliances are becoming increasingly prevalent, as companies recognize the need to collaborate to stay competitive. The competitive landscape is evolving, with a noticeable shift from price-based competition to a focus on innovation, technology, and supply chain reliability. This evolution suggests that future differentiation will hinge on the ability to deliver advanced technological solutions and sustainable practices.