North America : Market Leader in Innovation

North America is poised to maintain its leadership in the Industrial Laser Equipment Repair and Maintenance Market, holding a significant market share of 3.25 billion. The region's growth is driven by advanced manufacturing technologies, increasing automation, and stringent regulatory standards that promote equipment reliability and safety. The demand for high-precision laser systems in industries such as aerospace and automotive further fuels this growth.

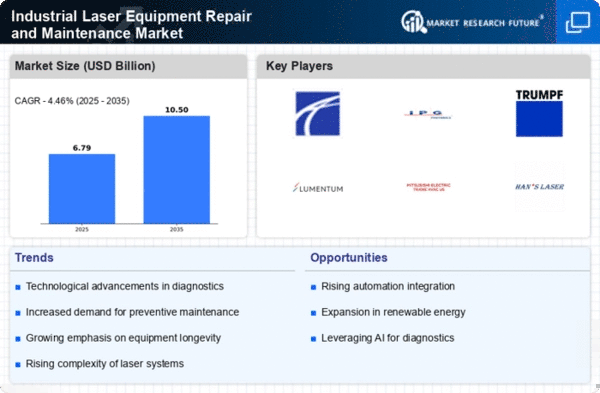

The competitive landscape in North America is robust, featuring key players like Coherent, IPG Photonics, and Lumentum. These companies are at the forefront of technological advancements, offering innovative repair solutions that enhance operational efficiency. The presence of a well-established supply chain and skilled workforce supports the region's market dominance, ensuring that North America remains a critical hub for laser equipment maintenance and repair.

Europe : Emerging Market with Growth Potential

Europe, with a market size of €1.8 billion, is witnessing a surge in the Industrial Laser Equipment Repair and Maintenance Market, driven by increasing investments in manufacturing and stringent environmental regulations. The region's focus on sustainability and energy efficiency is prompting industries to maintain their laser equipment to comply with regulations, thus enhancing demand for repair services. The European market is characterized by a growing emphasis on innovation and technology adoption.

Leading countries such as Germany and France are home to major players like TRUMPF and Laserline, which are pivotal in shaping the competitive landscape. The presence of these companies fosters a culture of innovation, ensuring that Europe remains competitive in the global market. The European Union's commitment to advancing manufacturing technologies further supports the growth of this sector, creating a favorable environment for repair and maintenance services.

Asia-Pacific : Rapidly Growing Industrial Sector

Asia-Pacific is emerging as a significant player in the Industrial Laser Equipment Repair and Maintenance Market, with a market size of $1.5 billion. The region's growth is fueled by rapid industrialization, increasing demand for high-quality manufacturing, and a shift towards automation. Countries like China and Japan are leading this transformation, with investments in advanced laser technologies driving the need for reliable maintenance services. Regulatory frameworks are also evolving to support industry standards and safety measures.

China, with companies like Han's Laser and SENFENG, is at the forefront of this market, contributing to a competitive landscape that is rapidly expanding. The presence of major manufacturers and a growing number of small and medium enterprises (SMEs) are enhancing service offerings in the region. As the demand for precision and efficiency rises, the focus on laser equipment maintenance is expected to grow, positioning Asia-Pacific as a key market player.

Middle East and Africa : Emerging Market with Untapped Potential

The Middle East and Africa region, with a market size of $0.95 billion, presents significant growth opportunities in the Industrial Laser Equipment Repair and Maintenance Market. The region is experiencing a gradual shift towards advanced manufacturing technologies, driven by government initiatives aimed at diversifying economies and enhancing industrial capabilities. The demand for laser equipment is increasing, particularly in sectors like construction and manufacturing, which is expected to boost repair and maintenance services.

Countries such as South Africa and the UAE are leading the charge, with investments in infrastructure and technology. The competitive landscape is evolving, with both local and international players entering the market. As the region continues to develop its industrial base, the need for reliable laser equipment maintenance will become increasingly critical, paving the way for future growth.