North America : Market Leader in Repair Services

North America is poised to maintain its leadership in the Industrial Electric Motor Repair and Maintenance Market, holding a market size of $2.25B in 2025. Key growth drivers include the increasing demand for energy-efficient motors and stringent regulations promoting sustainability. The region's advanced manufacturing sector and technological innovations further bolster market expansion, with a projected growth rate of 5% annually.

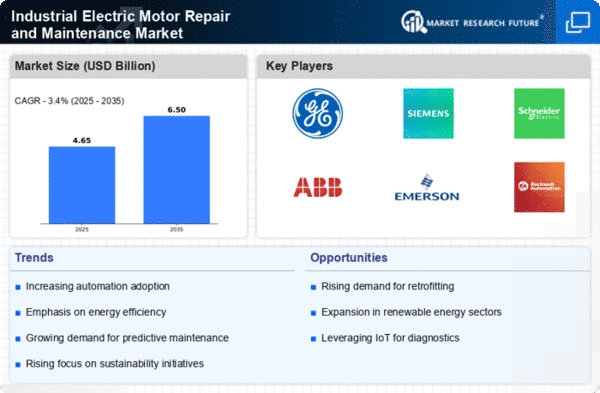

The United States and Canada are the leading countries, with major players like General Electric, Siemens, and Emerson Electric dominating the landscape. The competitive environment is characterized by a mix of established firms and emerging startups, all vying for market share. The presence of robust supply chains and skilled labor enhances the region's attractiveness for investment in motor repair services.

Europe : Emerging Market with Growth Potential

Europe's Industrial Electric Motor Repair and Maintenance Market is valued at $1.5B, driven by increasing industrial automation and a shift towards renewable energy sources. Regulatory frameworks, such as the EU's Green Deal, are catalyzing investments in energy-efficient technologies, which is expected to boost market growth by 4% annually. The region's focus on sustainability and innovation is reshaping demand dynamics.

Germany, France, and the UK are the leading countries in this market, with key players like Siemens and Schneider Electric at the forefront. The competitive landscape is evolving, with a mix of traditional firms and new entrants focusing on advanced repair technologies. The presence of strong regulatory support and funding initiatives further enhances the market's growth prospects.

Asia-Pacific : Rapid Growth in Emerging Economies

The Asia-Pacific region, with a market size of $0.9B, is witnessing rapid growth in the Industrial Electric Motor Repair and Maintenance Market, driven by industrialization and urbanization. Countries like China and India are investing heavily in infrastructure and manufacturing, leading to increased demand for electric motors. The region is expected to grow at a rate of 6% annually, fueled by government initiatives promoting energy efficiency.

China is the dominant player, followed by India and Japan, with key companies like Mitsubishi Electric and Nidec Corporation leading the market. The competitive landscape is marked by a mix of local and international players, all striving to capture the growing demand. The region's focus on technological advancements and skilled labor availability further enhances its market potential.

Middle East and Africa : Emerging Market with Untapped Potential

The Middle East and Africa region, valued at $0.35B, presents significant growth opportunities in the Industrial Electric Motor Repair and Maintenance Market. The increasing industrial activities and investments in infrastructure are driving demand for electric motor services. Regulatory support for energy efficiency and sustainability initiatives is expected to propel market growth by 5% annually.

Countries like South Africa and the UAE are leading the market, with a growing presence of international players. The competitive landscape is evolving, with local firms expanding their capabilities to meet rising demand. The region's untapped potential and focus on modernization make it an attractive market for investment in motor repair services.