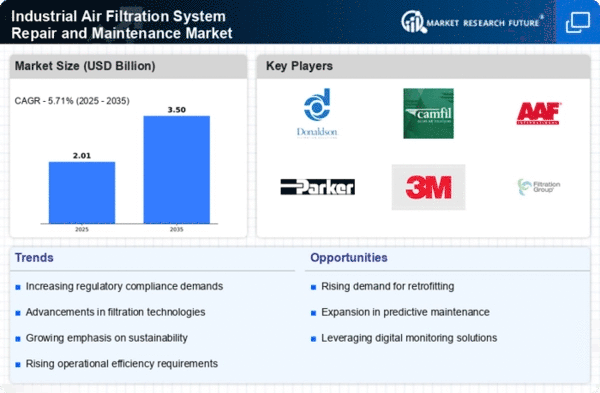

The Industrial Air Filtration System Repair and Maintenance Market is characterized by a competitive landscape that is increasingly shaped by innovation, sustainability, and digital transformation. Key players such as Donaldson Company (US), Camfil (SE), and Parker Hannifin Corporation (US) are actively pursuing strategies that enhance their market positioning. Donaldson Company (US) focuses on expanding its product portfolio through technological advancements, while Camfil (SE) emphasizes sustainability in its operations, aiming to reduce environmental impact. Parker Hannifin Corporation (US) is leveraging digital solutions to optimize maintenance processes, thereby improving operational efficiency. Collectively, these strategies contribute to a dynamic competitive environment where adaptability and forward-thinking are paramount.In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and enhance supply chain resilience. The market structure appears moderately fragmented, with several key players holding substantial market shares. This fragmentation allows for a diverse range of offerings, yet the influence of major companies remains significant, as they set benchmarks for quality and innovation.

In November Donaldson Company (US) announced the launch of a new line of eco-friendly filters designed to meet stringent environmental regulations. This strategic move not only aligns with global sustainability trends but also positions the company as a leader in environmentally responsible filtration solutions. The introduction of these products is likely to attract environmentally conscious customers and enhance brand loyalty.

In October Camfil (SE) expanded its operations in North America by acquiring a local filtration company. This acquisition is expected to bolster Camfil's market presence and enhance its ability to serve a growing customer base in the region. By integrating local expertise and resources, Camfil aims to streamline its operations and improve service delivery, which could lead to increased market share.

In September Parker Hannifin Corporation (US) launched a predictive maintenance platform that utilizes AI to monitor air filtration systems in real-time. This innovative solution is designed to reduce downtime and maintenance costs for clients, thereby enhancing operational efficiency. The integration of AI into their service offerings reflects a broader trend towards digitalization in the industry, positioning Parker Hannifin as a forward-thinking player in the market.

As of December the competitive trends in the Industrial Air Filtration System Repair and Maintenance Market are increasingly defined by digitalization, sustainability, and strategic alliances. Companies are forming partnerships to enhance their technological capabilities and expand their service offerings. The shift from price-based competition to a focus on innovation and supply chain reliability is evident, suggesting that future competitive differentiation will hinge on the ability to deliver advanced, sustainable solutions that meet evolving customer needs.