Rising Labor Costs

Labor costs have been steadily rising across various sectors, prompting manufacturers to seek cost-effective solutions. The Glass Handling Robot Market is benefiting from this trend, as companies look to automate labor-intensive processes. By deploying glass handling robots, businesses can significantly reduce their reliance on manual labor, thereby lowering operational costs. Reports suggest that labor costs in manufacturing have increased by over 20% in the past decade, making automation an attractive alternative. Furthermore, the implementation of robots not only mitigates labor expenses but also enhances operational efficiency. As a result, the Glass Handling Robot Market is likely to expand as more companies recognize the financial advantages of investing in robotic technologies.

Sustainability Initiatives

Sustainability has emerged as a pivotal concern for industries worldwide, influencing the Glass Handling Robot Market. Manufacturers are increasingly adopting eco-friendly practices, and automation plays a crucial role in achieving sustainability goals. Glass handling robots contribute to reduced waste and energy consumption, aligning with the growing demand for environmentally responsible production methods. The market for sustainable manufacturing technologies is expected to expand significantly, with a projected growth rate of 10% over the next few years. By integrating robotic solutions, companies can enhance their sustainability efforts while maintaining operational efficiency. Thus, the Glass Handling Robot Market is likely to see increased investment as businesses strive to meet sustainability targets.

Growing Emphasis on Quality Control

Quality control remains a critical focus within the Glass Handling Robot Market. As consumer expectations for product quality continue to rise, manufacturers are compelled to adopt advanced technologies that ensure precision and consistency. Glass handling robots are equipped with sophisticated sensors and vision systems that enable them to perform intricate tasks with high accuracy. This capability is essential in minimizing defects and ensuring that products meet stringent quality standards. The market for quality assurance technologies is projected to grow at a rate of 12% annually, reflecting the increasing importance of quality in manufacturing processes. Consequently, the Glass Handling Robot Market is likely to thrive as companies prioritize quality control through automation.

Technological Innovations in Robotics

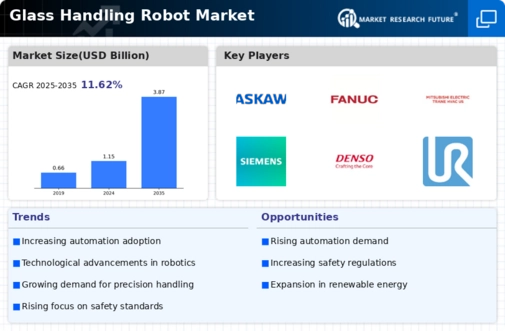

Technological innovations are reshaping the landscape of the Glass Handling Robot Market. Advancements in artificial intelligence, machine learning, and robotics are enabling the development of more sophisticated glass handling solutions. These innovations enhance the capabilities of robots, allowing them to perform complex tasks with greater efficiency and adaptability. The market for robotics technology is anticipated to grow at a compound annual growth rate of 14%, driven by the continuous evolution of robotic systems. As manufacturers seek to leverage these advancements, the Glass Handling Robot Market is expected to benefit from increased adoption of cutting-edge robotic solutions that improve operational performance and flexibility.

Increased Demand for Efficient Production

The Glass Handling Robot Market is experiencing a surge in demand for efficient production processes. As manufacturers strive to enhance productivity, the integration of glass handling robots has become a strategic priority. These robots are designed to streamline operations, reduce cycle times, and minimize human error. In recent years, the market has seen a notable increase in the adoption of automation technologies, with projections indicating a compound annual growth rate of approximately 15% over the next five years. This trend is driven by the need for manufacturers to remain competitive while meeting the growing demand for high-quality glass products. Consequently, the Glass Handling Robot Market is poised for substantial growth as companies invest in advanced robotic solutions to optimize their production lines.