Sustainability Initiatives in Gear Honing Machine Market

Sustainability initiatives are becoming a pivotal driver in the Gear Honing Machine Market. Manufacturers are increasingly focusing on eco-friendly practices, which include reducing waste and energy consumption during the honing process. The adoption of water-based coolants and biodegradable lubricants is on the rise, aligning with global environmental standards. Additionally, companies are investing in energy-efficient machines that minimize carbon footprints. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers. As sustainability becomes a core business strategy, the market is expected to witness a surge in demand for machines that support these initiatives, potentially leading to a market growth rate of around 4.8% in the coming years.

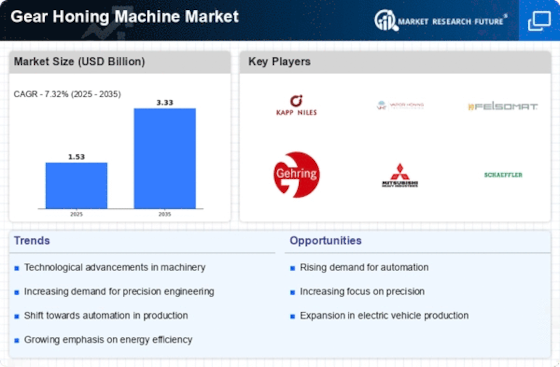

Technological Advancements in Gear Honing Machine Market

The Gear Honing Machine Market is experiencing a notable transformation due to rapid technological advancements. Innovations in automation and precision engineering are enhancing the efficiency and accuracy of honing processes. For instance, the integration of CNC technology allows for more complex geometries and tighter tolerances, which are increasingly demanded by manufacturers. Furthermore, advancements in software solutions enable real-time monitoring and data analytics, facilitating predictive maintenance and reducing downtime. As a result, companies are likely to invest in modern honing machines to remain competitive. The market is projected to grow at a compound annual growth rate of approximately 5.2% over the next five years, driven by these technological improvements.

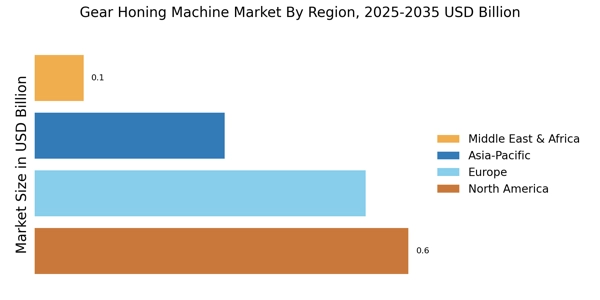

Emerging Markets and Economic Growth in Gear Honing Machine Market

Emerging markets are playing a crucial role in the Gear Honing Machine Market, driven by economic growth and industrialization. Countries in Asia and South America are witnessing a surge in manufacturing activities, leading to increased investments in advanced machinery, including honing machines. The rise of small and medium enterprises in these regions is also contributing to market expansion, as these companies seek to improve their production capabilities. Economic forecasts suggest that these emerging markets could experience a growth rate of approximately 7% in the honing machine sector over the next few years, reflecting the increasing demand for high-quality manufacturing solutions.

Rising Demand from Automotive Sector in Gear Honing Machine Market

The automotive sector is a significant contributor to the Gear Honing Machine Market, with increasing demand for high-precision components. As vehicles become more sophisticated, the need for finely honed gears that ensure optimal performance is paramount. The trend towards electric vehicles is also influencing this market, as manufacturers require specialized honing processes for new materials and designs. Reports indicate that the automotive industry accounts for nearly 40% of the total demand for honing machines, highlighting its critical role. This rising demand is expected to propel the market forward, with projections suggesting a growth rate of approximately 6% over the next few years.

Expansion of Aerospace and Defense Applications in Gear Honing Machine Market

The expansion of aerospace and defense applications is significantly impacting the Gear Honing Machine Market. As the aerospace sector continues to grow, the demand for high-performance components that require precise honing is increasing. The need for lightweight and durable materials in aircraft manufacturing necessitates advanced honing techniques to achieve the required specifications. Furthermore, defense contracts often require stringent quality standards, driving the need for reliable honing machines. This sector is anticipated to contribute to a market growth rate of around 5.5% in the coming years, as manufacturers seek to enhance their capabilities to meet these rigorous demands.