Expansion in Wind Energy Applications

The wind energy sector is increasingly utilizing fiber reinforced composites for turbine blades and other structural components. These materials provide the necessary strength and durability to withstand harsh environmental conditions while maintaining a lightweight profile. As the demand for renewable energy sources continues to rise, the fiber reinforced composite market is expected to experience substantial growth in this application area. By 2025, the market for composites in wind energy is projected to grow at a rate of around 9%, driven by the need for more efficient and longer-lasting wind turbines. This expansion not only supports the transition to renewable energy but also highlights the versatility of fiber reinforced composites in addressing the challenges of modern energy production.

Increasing Demand in Aerospace Sector

The aerospace sector is witnessing a notable surge in the adoption of fiber reinforced composites due to their lightweight and high-strength properties. This trend is driven by the industry's need to enhance fuel efficiency and reduce emissions. In 2025, the fiber reinforced composite market is projected to account for a substantial share of the aerospace materials market, with estimates suggesting a growth rate of approximately 7% annually. The integration of these materials in aircraft structures, components, and interiors is likely to bolster the overall market, as manufacturers seek to comply with stringent regulations and improve performance metrics. As a result, the fiber reinforced composite market is positioned to benefit significantly from this increasing demand, potentially leading to innovations in material formulations and processing techniques.

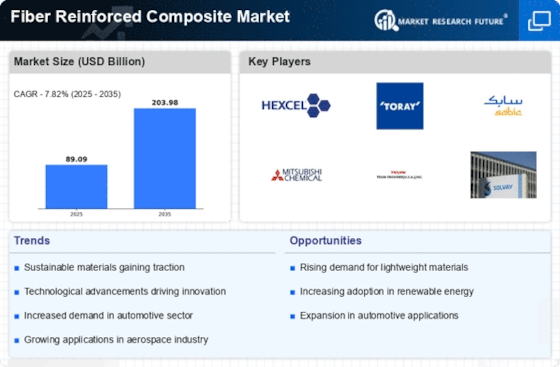

Growing Focus on Sustainable Materials

The increasing emphasis on sustainability is driving the fiber reinforced composite market towards the development of eco-friendly materials. Manufacturers are exploring bio-based fibers and recyclable resins to meet consumer demand for sustainable products. This shift is particularly evident in sectors such as construction and automotive, where environmental regulations are becoming more stringent. By 2025, the fiber reinforced composite market is projected to see a rise in the adoption of sustainable composites, with market analysts estimating a growth rate of approximately 8% in this segment. This trend not only aligns with global sustainability goals but also encourages innovation in material science, leading to the creation of composites that offer both performance and environmental benefits.

Advancements in Manufacturing Technologies

Recent advancements in manufacturing technologies are playing a pivotal role in the growth of the fiber reinforced composite market. Innovations such as automated fiber placement and 3D printing are enhancing production efficiency and reducing costs. These technologies enable manufacturers to produce complex geometries and tailor material properties to specific applications, which is particularly beneficial in industries like aerospace and automotive. As of 2025, the fiber reinforced composite market is anticipated to experience a significant uptick in production capabilities, with estimates suggesting a potential increase in output by 15% due to these technological improvements. This evolution in manufacturing processes not only streamlines operations but also opens avenues for new applications, thereby expanding the market's reach and fostering competitive advantages.

Rising Applications in Automotive Manufacturing

The automotive industry is increasingly incorporating fiber reinforced composites to enhance vehicle performance and safety. These materials offer superior strength-to-weight ratios, which contribute to improved fuel efficiency and reduced carbon footprints. In 2025, the fiber reinforced composite market is expected to capture a considerable portion of the automotive materials market, with projections indicating a compound annual growth rate of around 6%. This growth is fueled by the shift towards electric vehicles and the need for lightweight materials that can withstand rigorous safety standards. Consequently, the fiber reinforced composite market is likely to see expanded applications in various automotive components, including body panels, structural reinforcements, and interior parts, thereby driving further innovation and investment in this sector.