Advancements in Electronics

In the realm of electronics, the Global Cyanate Ester Resin Market Industry benefits from the increasing complexity and miniaturization of electronic devices. Cyanate esters are utilized in the production of printed circuit boards and other electronic components due to their excellent thermal stability and dielectric properties. As the demand for high-performance electronics escalates, particularly in telecommunications and consumer electronics, the market is expected to grow significantly. By 2035, the market could reach 2.4 USD Billion, reflecting the essential role of cyanate esters in supporting the evolving needs of the electronics industry.

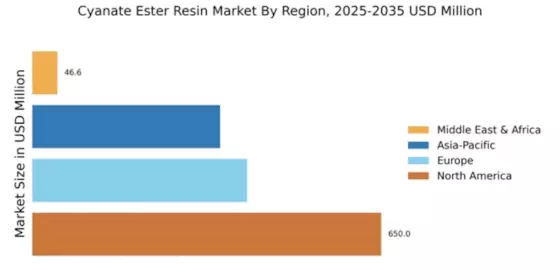

Market Trends and Projections

The Global Cyanate Ester Resin Market Industry exhibits various trends and projections that highlight its growth trajectory. The market is anticipated to reach 1.45 USD Billion by 2024, with a projected increase to 2.4 USD Billion by 2035. The compound annual growth rate of 4.68% from 2025 to 2035 indicates a steady expansion, driven by diverse applications across aerospace, electronics, automotive, and renewable energy sectors. These trends suggest a robust demand for cyanate esters, reflecting their critical role in advancing technology and sustainability across multiple industries.

Innovations in Material Science

Innovations in material science are significantly influencing the Global Cyanate Ester Resin Market Industry. Research and development efforts are focused on enhancing the properties of cyanate esters, leading to the creation of new formulations that offer improved performance characteristics. These advancements may include increased thermal stability, enhanced adhesion, and better processing capabilities. As industries seek materials that can withstand extreme conditions, the demand for innovative cyanate ester formulations is likely to rise, potentially leading to a more dynamic market landscape as manufacturers adapt to evolving technological requirements.

Growing Demand in Aerospace Sector

The Global Cyanate Ester Resin Market Industry experiences a notable surge in demand driven by the aerospace sector. The lightweight and high-performance characteristics of cyanate esters make them ideal for aerospace applications, where reducing weight while maintaining structural integrity is crucial. As commercial and military aircraft manufacturers increasingly adopt advanced composite materials, the market is projected to reach 1.45 USD Billion in 2024. This growth is indicative of the industry's shift towards materials that enhance fuel efficiency and performance, suggesting a robust future as the aerospace sector continues to innovate.

Emerging Applications in Renewable Energy

The Global Cyanate Ester Resin Market Industry is poised for growth due to emerging applications in the renewable energy sector. As the world shifts towards sustainable energy solutions, cyanate esters are increasingly utilized in wind turbine blades and solar panel components. Their superior mechanical properties and resistance to environmental degradation make them suitable for these applications. The ongoing investments in renewable energy infrastructure are likely to drive demand for cyanate esters, suggesting a potential for significant market expansion in the coming years as the industry aligns with global sustainability goals.

Rising Adoption in Automotive Applications

The automotive industry increasingly adopts cyanate ester resins, contributing to the expansion of the Global Cyanate Ester Resin Market Industry. These resins are favored for their lightweight and durable properties, which are essential for enhancing fuel efficiency and performance in vehicles. As manufacturers strive to meet stringent environmental regulations and consumer demand for sustainable solutions, the use of cyanate esters in automotive applications is likely to grow. This trend may lead to a compound annual growth rate of 4.68% from 2025 to 2035, indicating a promising future for cyanate esters in the automotive sector.