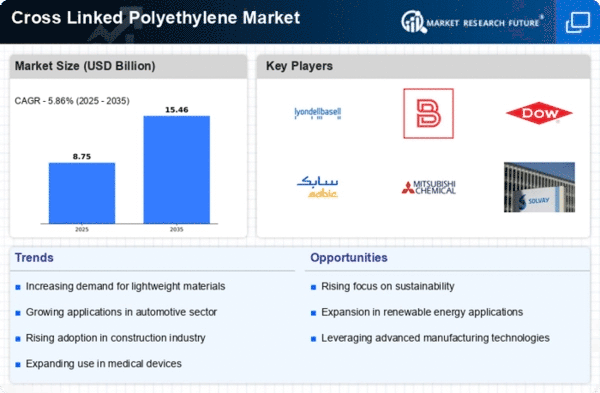

Market Growth Projections

The Global Cross-Linked Polyethylene (XLPE) Market Industry is projected to experience substantial growth over the coming years. With a market value of 7.37 USD Billion in 2024, it is anticipated to expand significantly, reaching 15.8 USD Billion by 2035. This growth trajectory reflects a compound annual growth rate (CAGR) of 7.18% from 2025 to 2035. Such projections underscore the increasing adoption of XLPE across various sectors, driven by its advantageous properties and applications. The market's expansion is likely to be fueled by ongoing technological advancements, rising demand in electrical and construction applications, and a growing emphasis on sustainability.

Growth in Construction Sector

The construction sector plays a pivotal role in the expansion of the Global Cross-Linked Polyethylene (XLPE) Market Industry. XLPE is utilized in various construction applications, including plumbing, heating, and flooring systems, due to its durability and resistance to chemicals. As urbanization accelerates globally, the demand for advanced materials that enhance building longevity and efficiency is rising. The construction industry's growth is anticipated to contribute significantly to the market's expansion, with a projected CAGR of 7.18% from 2025 to 2035. This growth is indicative of a broader trend towards sustainable building practices and the adoption of innovative materials in construction.

Rising Demand in Electrical Applications

The Global Cross-Linked Polyethylene (XLPE) Market Industry experiences a notable surge in demand driven by its extensive use in electrical insulation applications. XLPE is favored for its superior dielectric properties, thermal stability, and resistance to moisture, making it ideal for high-voltage cables. As the global energy sector transitions towards renewable sources, the need for efficient and reliable cable insulation is paramount. In 2024, the market is projected to reach 7.37 USD Billion, reflecting the increasing investments in infrastructure and energy projects. This trend is expected to continue, with the market potentially reaching 15.8 USD Billion by 2035, indicating a robust growth trajectory fueled by electrical applications.

Market Dynamics and Competitive Landscape

The Global Cross-Linked Polyethylene (XLPE) Market Industry is characterized by dynamic market forces and a competitive landscape. Key players are focusing on strategic partnerships, mergers, and acquisitions to enhance their market presence and expand product offerings. This competitive environment fosters innovation and drives the development of new applications for XLPE. As companies invest in research and development, the market is likely to see the introduction of advanced XLPE products that cater to specific industry needs. The interplay of these market dynamics is expected to shape the industry's future, influencing pricing strategies and market share distribution among leading manufacturers.

Advancements in Manufacturing Technologies

Technological advancements in the production of Cross-Linked Polyethylene (XLPE) are driving efficiency and quality in the Global XLPE Market Industry. Innovations such as the silane method and electron beam cross-linking have enhanced the material's properties, leading to improved performance in various applications. These advancements not only reduce production costs but also enable manufacturers to meet stringent quality standards. As a result, the market is likely to witness increased adoption of XLPE in diverse sectors, including automotive and telecommunications. The ongoing evolution of manufacturing technologies suggests a promising future for the industry, with potential for expanded applications and market penetration.

Environmental Regulations and Sustainability

Increasing environmental regulations are influencing the Global Cross-Linked Polyethylene (XLPE) Market Industry, as industries seek sustainable alternatives to traditional materials. XLPE is recognized for its recyclability and lower environmental impact compared to conventional polyethylene. As governments worldwide implement stricter regulations on plastic usage and waste management, the demand for eco-friendly materials is expected to rise. This shift towards sustainability is likely to drive innovation in XLPE production processes and applications, fostering a more environmentally responsible market. The industry's adaptability to these regulations may enhance its competitive edge in the global market, positioning XLPE as a preferred choice for environmentally conscious consumers.