Enhanced Quality Control

Quality control is a critical aspect of manufacturing, and the Global Artificial Intelligence (AI) in Manufacturing Market Industry is increasingly leveraging AI to enhance this process. AI systems can analyze vast amounts of data in real-time, identifying defects and inconsistencies that human inspectors might overlook. For example, AI-powered visual inspection systems can detect anomalies in products with over 95% accuracy. This capability not only reduces waste but also ensures that products meet stringent quality standards. As manufacturers strive to maintain competitiveness, the integration of AI in quality control processes is likely to become a standard practice.

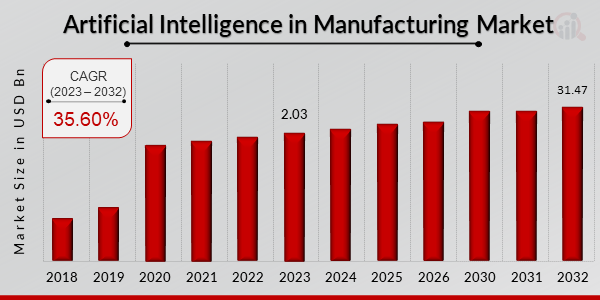

Market Growth Projections

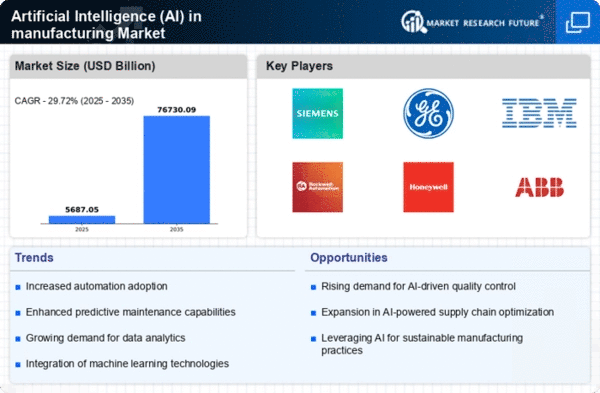

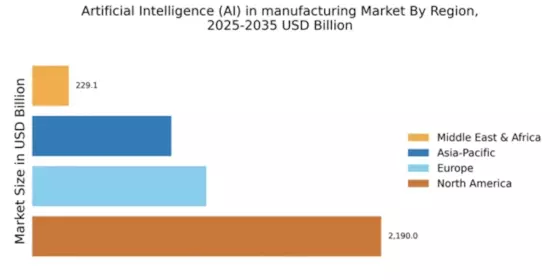

The Global Artificial Intelligence (AI) in Manufacturing Market Industry is poised for substantial growth, with projections indicating a market size of 3.5 USD Billion in 2024 and an anticipated increase to 22.5 USD Billion by 2035. This growth represents a compound annual growth rate (CAGR) of 18.43% from 2025 to 2035. The increasing adoption of AI technologies across various manufacturing sectors underscores the industry's commitment to innovation and efficiency. As manufacturers continue to integrate AI into their operations, the market is expected to expand significantly, reflecting the transformative impact of AI on the manufacturing landscape.

Supply Chain Optimization

The Global Artificial Intelligence (AI) in Manufacturing Market Industry is also driven by the need for supply chain optimization. AI technologies facilitate better demand forecasting, inventory management, and logistics planning. By analyzing historical data and market trends, AI can predict fluctuations in demand, allowing manufacturers to adjust their production schedules accordingly. This adaptability can lead to a reduction in excess inventory and associated costs. As the market is expected to grow to 22.5 USD Billion by 2035, the role of AI in enhancing supply chain efficiency is becoming increasingly vital for manufacturers aiming to remain agile in a dynamic market.

Data-Driven Decision Making

The Global Artificial Intelligence (AI) in Manufacturing Market Industry is increasingly characterized by a shift towards data-driven decision making. AI systems can process and analyze large datasets, providing insights that inform strategic decisions. This capability allows manufacturers to identify trends, optimize processes, and enhance product development. For instance, companies utilizing AI analytics have reported improved decision-making speed by up to 50%. As the industry evolves, the ability to harness data effectively will likely become a key differentiator for manufacturers, driving further investment in AI technologies.

Labor Shortages and Skill Gaps

Labor shortages and skill gaps present significant challenges in the Global Artificial Intelligence (AI) in Manufacturing Market Industry. As the workforce ages and fewer skilled workers enter the field, manufacturers are turning to AI to fill these gaps. Automation and AI-driven systems can perform repetitive tasks, allowing human workers to focus on more complex responsibilities. This shift not only addresses labor shortages but also enhances overall productivity. The increasing reliance on AI solutions is indicative of a broader trend where manufacturers seek to leverage technology to mitigate workforce challenges and maintain operational continuity.

Increased Efficiency and Productivity

The Global Artificial Intelligence (AI) in Manufacturing Market Industry is witnessing a surge in demand for solutions that enhance efficiency and productivity. AI technologies, such as machine learning and predictive analytics, enable manufacturers to optimize operations by minimizing downtime and streamlining processes. For instance, companies employing AI-driven predictive maintenance have reported reductions in equipment failure rates by up to 30%. This efficiency translates into significant cost savings and improved output quality. As the market is projected to reach 3.5 USD Billion in 2024, the drive towards operational excellence remains a pivotal factor in the industry's growth.