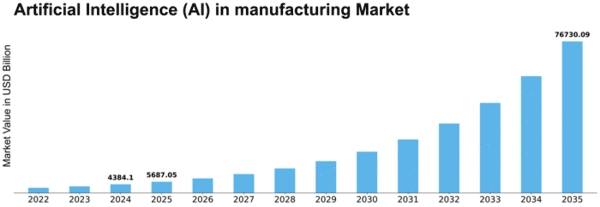

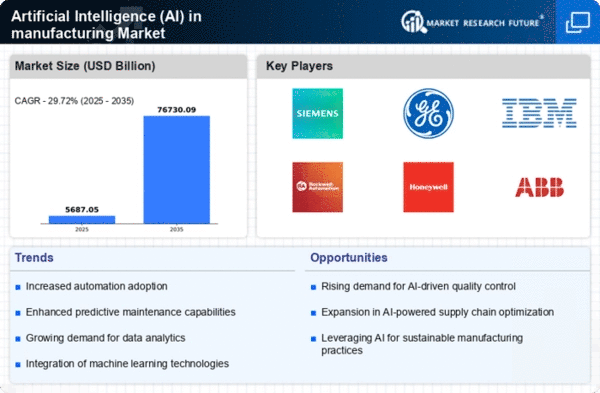

Artificial Intelligence Ai In Manufacturing Size

Artificial Intelligence (AI) in manufacturing Market Growth Projections and Opportunities

The market factors influencing the adoption and evolution of Artificial Intelligence (AI) in the manufacturing sector are multifaceted, reflecting a complex interplay of technological, economic, and operational dynamics. One significant factor is the relentless pursuit of operational efficiency and cost optimization. Manufacturers are increasingly turning to AI-driven solutions to streamline production processes, reduce downtime, and enhance overall operational efficiency. The potential for AI to analyze vast datasets, predict equipment failures, and optimize resource allocation aligns with the manufacturing industry's ongoing quest for lean and agile operations, making it a pivotal factor driving the adoption of AI technologies.

The growing complexity of manufacturing processes and the demand for more sophisticated products are key factors influencing the adoption of AI. As manufacturing becomes increasingly intricate, traditional approaches struggle to cope with the intricacies involved. AI, with its ability to process complex data patterns and learn from diverse datasets, offers a solution to navigate the complexities of modern manufacturing. This factor reflects the industry's recognition of AI as an enabler for handling intricate processes and delivering high-quality, technologically advanced products to meet market demands.

Another critical factor is the surge in data availability within manufacturing ecosystems. The proliferation of sensors, IoT devices, and interconnected machinery generates vast amounts of data. AI leverages this data to extract actionable insights, providing manufacturers with valuable information for decision-making. The availability of data is a driving force behind the integration of AI, enabling manufacturers to transition from reactive to proactive decision-making, optimize production workflows, and achieve a data-driven competitive advantage.

The trend towards Industry 4.0 and the adoption of smart manufacturing practices contribute significantly to the growth of AI in the manufacturing market. Industry 4.0 emphasizes the integration of digital technologies, including AI, into manufacturing processes, creating intelligent and interconnected ecosystems. The concept of smart factories leverages AI to enable real-time data analytics, predictive maintenance, and adaptive manufacturing. This factor reflects the broader industrial trend towards digital transformation, positioning AI as a central element in reshaping the future of manufacturing.

Supply chain optimization is a compelling factor influencing the adoption of AI in manufacturing. The complexity of global supply chains, coupled with the need for just-in-time production, demands a level of responsiveness and flexibility that traditional approaches struggle to provide. AI-driven solutions enhance supply chain visibility, improve demand forecasting, and optimize inventory management, addressing the challenges associated with globalized manufacturing. This factor underscores the role of AI in creating resilient and adaptive supply chain networks.

Market factors also include the increasing emphasis on quality control and defect detection in manufacturing processes. AI, particularly through machine vision systems, enables real-time inspection and identification of defects in products. Manufacturers are adopting AI-driven quality control to enhance product quality, reduce waste, and ensure compliance with industry standards. This factor aligns with the industry's commitment to delivering high-quality products and meeting stringent quality assurance requirements through the integration of AI technologies.

The shortage of skilled labor in manufacturing is another factor influencing the adoption of AI. As the industry grapples with a diminishing pool of skilled workers, AI-driven automation becomes a strategic imperative. Manufacturers are turning to AI-powered robotic systems and collaborative robots to augment human labor, mitigate the impact of the skills gap, and optimize production processes. This factor reflects the industry's proactive approach to addressing workforce challenges through the integration of AI-driven technologies.

Data security and privacy considerations play a crucial role in shaping the market factors for AI in manufacturing. With the increasing reliance on AI to analyze sensitive production data, manufacturers are prioritizing robust cybersecurity measures and compliance frameworks. Ensuring the security and privacy of data generated and processed by AI systems becomes paramount, influencing the selection and deployment of AI solutions in manufacturing environments.

Leave a Comment