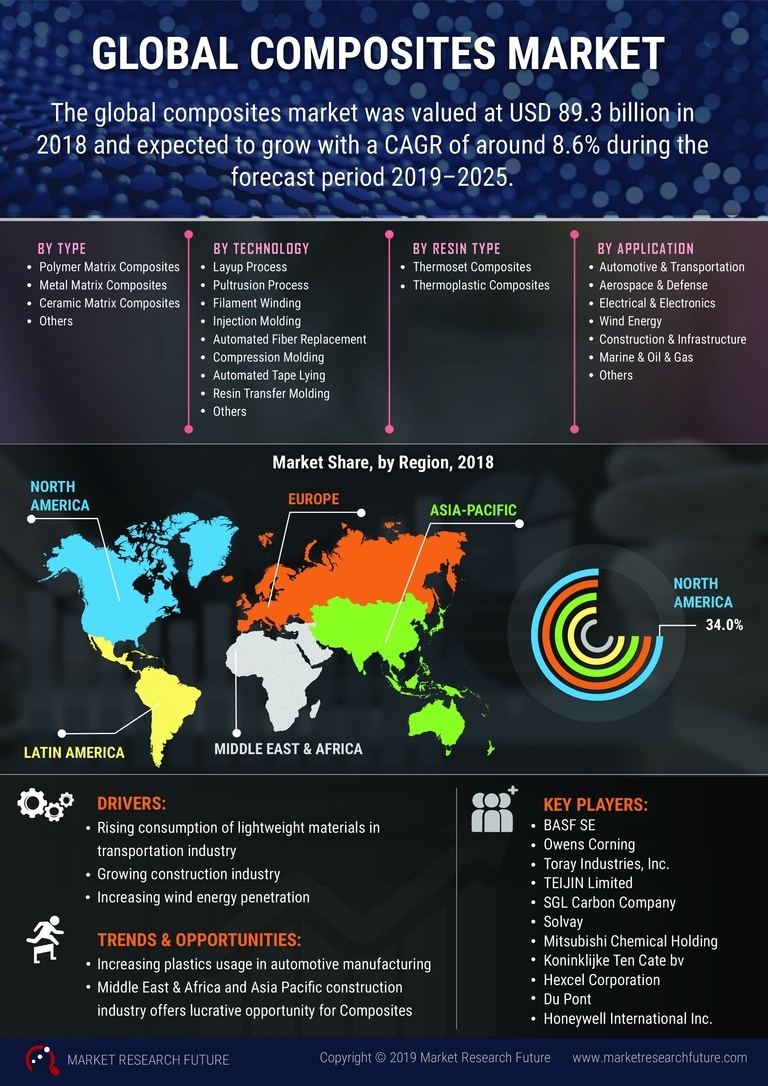

The Composites Market is characterized by the presence of , regional, and local players. The market is highly consolidated, with all the players competing to gain significant market share. The key market players of Composites Market compete based on cost, product quality, availability of raw materials, and durability of the product. There has been substantial revenue growth for selected composite companies, particularly those located in Asia or those with major operations in Asia. This is the result of an increased domestic demand within Asian countries, as well as an overall rise in composite demand across the globe.

However, some major companies produce more than one of the composites. A clear example is Teijin, which produces carbon fiber as well as aramid fiber.

PPG Industries, Inc. (US), Hexion (US), Jushi Group Co., Ltd (China), Toray Industries Inc. (Japan), Owens Corning (US), Teijin Limited (Japan), Hexcel Corporation (US), SGL Carbon (Germany), Mitsubishi Chemicals Corporation (Japan), Solvay (Belgium), and Huntsman International LLC (US) are the key players operating in the Composites Market. The Composites Market remains highly fragmented with the majority of tier-1 players, with leaders, including PPG INDUSTRIES INC, Teijin Limited, Mitsubishi Chemical Corporation, Solvay, and Toray Industries Inc., accounting for the largest market share. Players in this market adopted various strategies to expand their footprint and augment their market share.

PPG Industries, Inc. (PPG), a leader in transportation and industrial coatings, is engaged in the production and distribution of a broad range of paints, coatings, and specialty materials. It caters to customers operating in a wide array of end-use industries, including automotive, aerospace, marine, and construction. PPG operates through two business segments, namely, performance and industrial coating. PPG manufactures an extensive portfolio of coatings systems through 156 manufacturing facilities and has a presence in over 39 countries across the globe and sales in more than 70 countries.

The company offers flooring coating products under the protective coating solutions offered by its performance coatings business segment.

Also, Hexion is engaged in the manufacturing of advanced specialty chemicals and performance materials. It is a leading manufacturer of adhesives and epoxy resins, and coatings. It operates through business segments, namely epoxy, phenolic and coating resins, and forest products resins. The epoxy, phenolic, and coating resins segment accounted for around USD 2,052 million by the end of 2017. The company serves diverse markets, such as architectural and industrial paints, packaging, consumer goods, automotive coatings, aviation, energy, oil & gas, and electrical composites.

Hexion has a worldwide network with production facilities in more than 90 countries severing to over 3,000 customers. Its customers include Akzo Nobel N.V., 3M, BASF, Bayer, Dow, Monsanto, PPG Industries, Owens Corning, Valspar, and Weyerhaeuser.