Growing Applications in Food Processing

The cold plasma processing Market is witnessing a notable increase in applications within the food processing sector. Cold plasma technology is being utilized for food sterilization, extending shelf life, and enhancing food safety without the use of chemicals. This method effectively reduces microbial load and preserves the nutritional quality of food products. Recent studies suggest that the cold plasma treatment can reduce pathogens by up to 99.9%, making it an attractive alternative for food manufacturers. As consumer awareness regarding food safety rises, the demand for cold plasma solutions in food processing is expected to escalate, potentially driving market growth significantly in the coming years.

Increased Focus on Sustainable Practices

The Cold Plasma Processing Market is experiencing a heightened focus on sustainable practices, which is reshaping market dynamics. As industries strive to reduce their environmental footprint, cold plasma technology emerges as a viable solution due to its eco-friendly nature. Unlike traditional chemical processes, cold plasma treatments often require minimal energy and produce fewer hazardous byproducts. This sustainability aspect is particularly appealing to sectors such as textiles and packaging, where there is a growing demand for greener alternatives. The market is likely to see an increase in investments aimed at developing sustainable cold plasma solutions, further driving growth in the coming years.

Regulatory Support for Innovative Technologies

The Cold Plasma Processing Market benefits from increasing regulatory support aimed at promoting innovative technologies. Governments and regulatory bodies are recognizing the potential of cold plasma applications in various sectors, including healthcare, agriculture, and environmental management. This support often translates into funding opportunities and incentives for research and development, which can accelerate the adoption of cold plasma technologies. For example, initiatives aimed at reducing chemical usage in agriculture are likely to favor cold plasma solutions, as they offer eco-friendly alternatives. Such regulatory frameworks may enhance market penetration and encourage investment in cold plasma processing technologies.

Rising Demand for Surface Modification Solutions

The Cold Plasma Processing Market is driven by a rising demand for surface modification solutions across various industries. Cold plasma technology is increasingly employed to enhance adhesion, wettability, and surface properties of materials, which is crucial in sectors such as automotive, aerospace, and electronics. The ability to modify surfaces without altering the bulk properties of materials is particularly appealing to manufacturers. Market data indicates that the surface modification segment is expected to account for a significant share of the cold plasma market, with projections suggesting a growth rate of around 12% annually. This trend underscores the importance of cold plasma processing in meeting the evolving needs of diverse industries.

Technological Advancements in Cold Plasma Processing

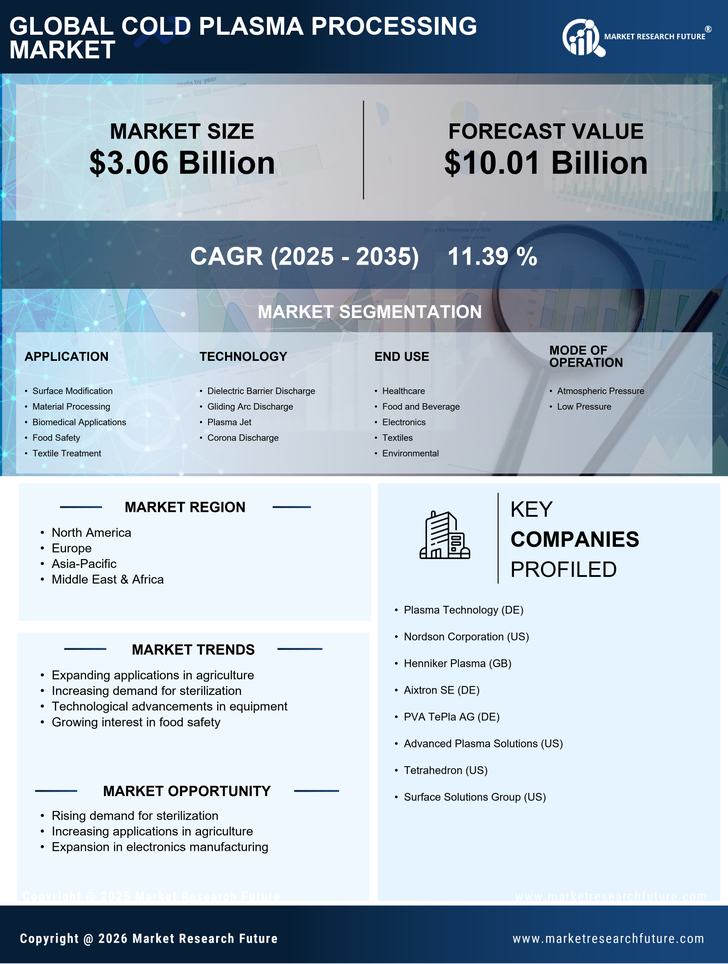

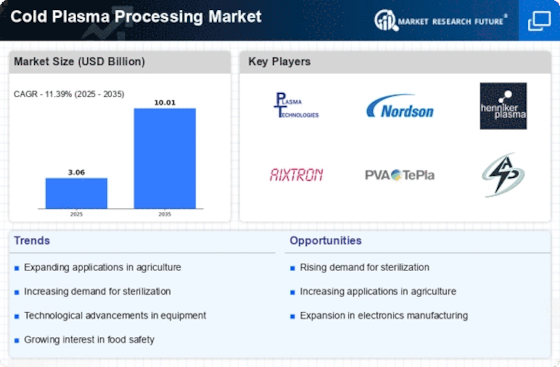

The Cold Plasma Processing Market is experiencing a surge in technological advancements that enhance the efficiency and effectiveness of plasma applications. Innovations in plasma generation techniques, such as dielectric barrier discharge and atmospheric pressure plasma jets, are becoming increasingly prevalent. These advancements not only improve the quality of surface modifications but also expand the range of materials that can be treated. For instance, the ability to process complex geometries and sensitive substrates is gaining traction, which could potentially lead to broader applications in sectors like electronics and textiles. As a result, the market is projected to grow at a compound annual growth rate of approximately 15% over the next five years, indicating a robust demand for advanced cold plasma technologies.