Growing Demand for Advanced Coatings

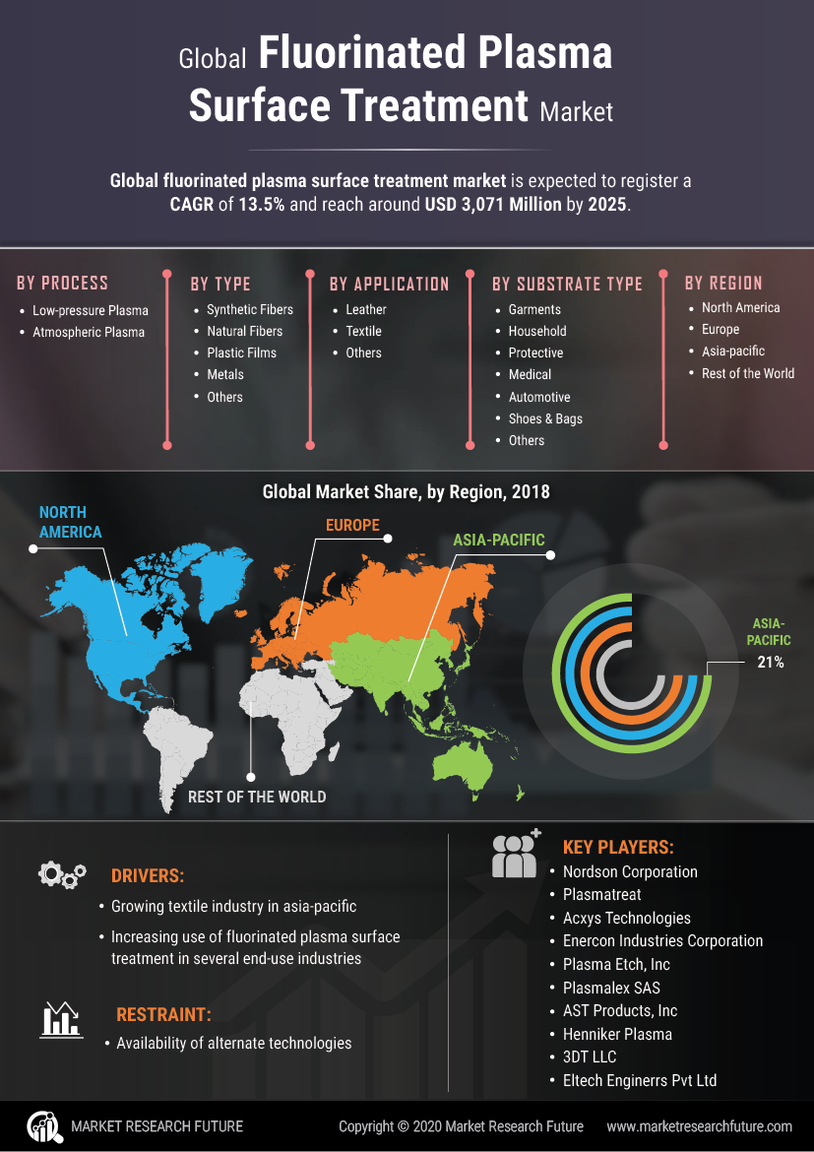

The Global Fluorinated Plasma Surface Treatment Market Industry experiences a notable surge in demand for advanced coatings across various sectors, including automotive, aerospace, and electronics. These coatings enhance surface properties such as hydrophobicity, chemical resistance, and wear resistance, which are critical for improving product longevity and performance. As industries increasingly prioritize durability and efficiency, the market is projected to reach 1.79 USD Billion in 2024, reflecting a growing recognition of the benefits provided by fluorinated plasma treatments. This trend suggests a robust future for the industry, as manufacturers seek innovative solutions to meet evolving consumer expectations.

Increasing Environmental Regulations

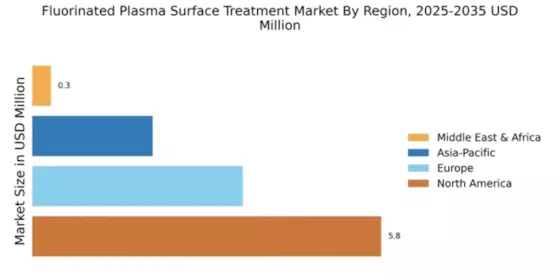

The Global Fluorinated Plasma Surface Treatment Market Industry is influenced by the rising stringency of environmental regulations aimed at reducing hazardous emissions and promoting sustainable practices. Governments worldwide are implementing policies that encourage the adoption of eco-friendly technologies, including plasma surface treatments that minimize waste and energy consumption. This regulatory landscape compels manufacturers to seek compliant solutions, thereby driving the demand for fluorinated plasma treatments. As industries adapt to these regulations, the market is poised for significant growth, with projections indicating a potential market size of 10.9 USD Billion by 2035, underscoring the importance of sustainability in future developments.

Expanding Applications in Electronics

The expanding applications of fluorinated plasma surface treatments in the electronics sector significantly contribute to the growth of the Global Fluorinated Plasma Surface Treatment Market Industry. These treatments are increasingly utilized for enhancing the performance of electronic components, such as semiconductors and circuit boards, by improving adhesion and reducing surface contamination. As the electronics industry continues to evolve with the advent of new technologies, the demand for efficient surface treatments is likely to increase. This trend not only supports the market's growth trajectory but also highlights the critical role of plasma treatments in ensuring the reliability and functionality of advanced electronic devices.

Rising Investment in Research and Development

Rising investment in research and development (R&D) within the Global Fluorinated Plasma Surface Treatment Market Industry is fostering innovation and expanding the scope of applications. Companies are increasingly allocating resources to explore new formulations and processes that enhance the effectiveness of plasma treatments. This focus on R&D is essential for developing tailored solutions that meet specific industry needs, thereby driving market growth. As organizations strive to maintain a competitive edge, the emphasis on innovation is expected to yield new products and technologies, further propelling the market forward in the coming years.

Technological Advancements in Plasma Treatment

Technological advancements play a pivotal role in shaping the Global Fluorinated Plasma Surface Treatment Market Industry. Innovations in plasma generation techniques and process optimization have led to enhanced treatment efficiency and effectiveness. For instance, the development of low-pressure plasma systems allows for better uniformity and control over surface modifications. These advancements not only improve the quality of surface treatments but also reduce operational costs, making them more accessible to a broader range of industries. As a result, the market is expected to witness a compound annual growth rate (CAGR) of 17.83% from 2025 to 2035, indicating a strong trajectory for growth driven by technology.