Market Growth Projections

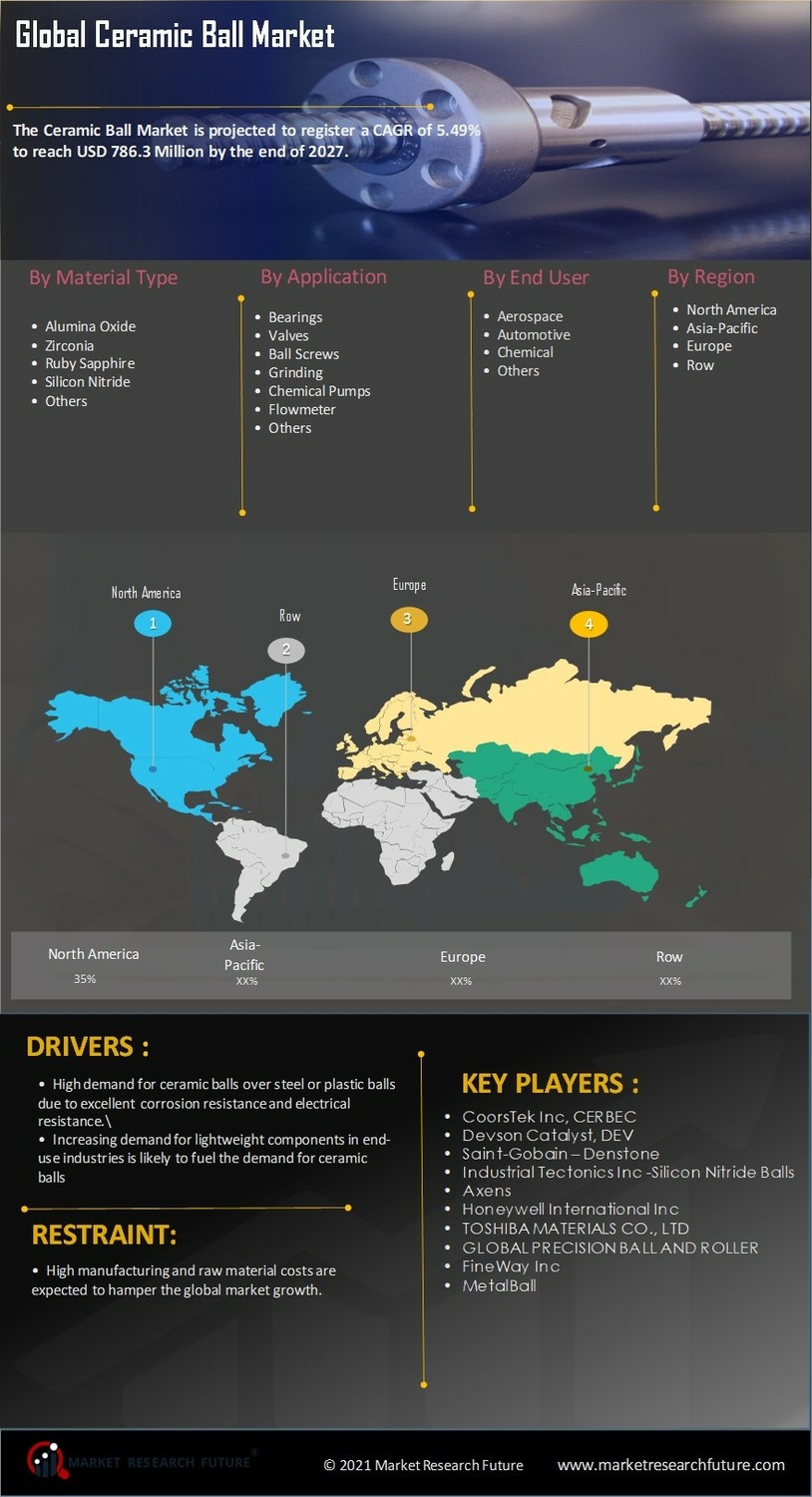

The Global Ceramic Ball Market Industry is poised for substantial growth, with projections indicating a market value of 2500 USD Million in 2024 and an anticipated increase to 4500 USD Million by 2035. This growth trajectory suggests a compound annual growth rate of 5.49% from 2025 to 2035, driven by rising demand across various sectors, including aerospace, automotive, and industrial applications. The increasing adoption of advanced materials and technologies is likely to further enhance the market's potential, positioning ceramic balls as a critical component in modern manufacturing and engineering.

Rising Demand in Aerospace Sector

The Global Ceramic Ball Market Industry is experiencing heightened demand from the aerospace sector, where ceramic balls are utilized for their lightweight and high-strength properties. The aerospace industry is increasingly adopting advanced materials to enhance fuel efficiency and performance. For instance, ceramic balls are employed in bearings and other critical components, contributing to reduced weight and improved durability. This trend is expected to drive the market's growth, with projections indicating a market value of 2500 USD Million in 2024, potentially reaching 4500 USD Million by 2035.

Expansion of Industrial Applications

The expansion of industrial applications is a notable driver for the Global Ceramic Ball Market Industry. Industries such as oil and gas, mining, and manufacturing are increasingly utilizing ceramic balls for their durability and performance under extreme conditions. For instance, ceramic balls are employed in pumps and valves, where their resistance to wear and chemical corrosion is critical. This diversification of applications is likely to contribute to the market's growth, with expectations of a compound annual growth rate of 5.49% from 2025 to 2035, reflecting the increasing reliance on ceramic materials in various industrial sectors.

Increasing Focus on Energy Efficiency

There is a growing emphasis on energy efficiency across multiple sectors, which is positively influencing the Global Ceramic Ball Market Industry. Ceramic balls, known for their low friction properties, are increasingly being used in applications that require energy-efficient solutions. For example, in industrial machinery and equipment, the use of ceramic balls can lead to significant energy savings and reduced operational costs. This trend aligns with global sustainability goals, potentially propelling the market towards a valuation of 4500 USD Million by 2035, as industries seek to adopt more sustainable practices.

Growing Applications in Automotive Industry

The automotive industry is a major driver of the Global Ceramic Ball Market Industry, as manufacturers increasingly incorporate ceramic balls into various components to enhance performance and longevity. Ceramic balls are utilized in applications such as bearings, valve seats, and fuel injectors, where their resistance to wear and corrosion is advantageous. The shift towards electric vehicles is also contributing to this trend, as these vehicles require high-performance materials to optimize efficiency. This growing demand is expected to support the market's expansion, with a projected value of 2500 USD Million in 2024.

Technological Advancements in Manufacturing

Technological innovations in the manufacturing processes of ceramic balls are significantly impacting the Global Ceramic Ball Market Industry. Advanced techniques such as additive manufacturing and precision machining are enhancing the quality and performance of ceramic balls. These advancements allow for the production of more complex geometries and improved surface finishes, which are crucial for applications in various industries, including automotive and electronics. As a result, the market is likely to witness a compound annual growth rate of 5.49% from 2025 to 2035, reflecting the increasing adoption of high-performance ceramic balls.