Increasing Infrastructure Investment

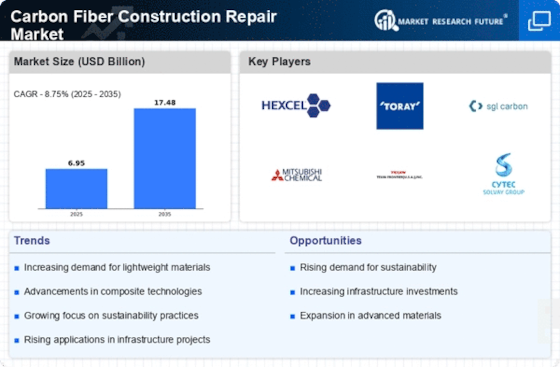

The Carbon Fiber Construction Repair Market is experiencing a surge in demand due to rising investments in infrastructure. Governments and private sectors are allocating substantial budgets for the maintenance and repair of aging structures. This trend is particularly evident in sectors such as transportation, where bridges and roads require durable solutions. The global infrastructure investment is projected to reach trillions of dollars in the coming years, creating a favorable environment for carbon fiber applications. The lightweight and high-strength properties of carbon fiber make it an ideal choice for reinforcing structures, thereby enhancing their longevity and safety. As infrastructure projects proliferate, the Carbon Fiber Construction Repair Market is poised for significant growth.

Growing Demand for Lightweight Materials

The Carbon Fiber Construction Repair Market is benefiting from the increasing demand for lightweight materials across various sectors. Industries such as aerospace, automotive, and construction are increasingly adopting carbon fiber due to its superior strength-to-weight ratio. This shift is driven by the need for energy efficiency and performance enhancement. For instance, in the automotive sector, manufacturers are utilizing carbon fiber to reduce vehicle weight, which in turn improves fuel efficiency. The construction industry is also recognizing the advantages of carbon fiber in reducing the overall weight of structures while maintaining structural integrity. This trend is likely to propel the Carbon Fiber Construction Repair Market forward as more sectors seek innovative solutions.

Rising Awareness of Repair and Maintenance Solutions

The Carbon Fiber Construction Repair Market is witnessing a heightened awareness regarding the importance of repair and maintenance solutions. As structures age, the need for effective repair methods becomes paramount. Carbon fiber offers a viable solution due to its durability and resistance to environmental factors. The market is seeing an increase in educational initiatives aimed at informing stakeholders about the benefits of carbon fiber repairs. This awareness is translating into higher adoption rates among construction firms and property owners. Furthermore, the global market for construction repair is expected to grow significantly, with carbon fiber emerging as a preferred material for its long-term benefits. This trend indicates a promising future for the Carbon Fiber Construction Repair Market.

Technological Innovations in Carbon Fiber Applications

The Carbon Fiber Construction Repair Market is being propelled by ongoing technological innovations in carbon fiber applications. Advancements in manufacturing processes and material science are enhancing the performance characteristics of carbon fiber composites. These innovations are leading to the development of more efficient and cost-effective repair solutions. For example, new bonding techniques and surface treatments are improving the adhesion of carbon fiber to existing structures, thereby increasing the effectiveness of repairs. As technology continues to evolve, the Carbon Fiber Construction Repair Market is likely to see an influx of novel applications and products, further driving market growth. The integration of smart technologies may also play a role in monitoring the condition of repaired structures.

Regulatory Support for Sustainable Construction Practices

The Carbon Fiber Construction Repair Market is benefiting from regulatory support aimed at promoting sustainable construction practices. Governments are increasingly implementing policies that encourage the use of environmentally friendly materials and methods in construction. Carbon fiber, known for its recyclability and low environmental impact, aligns well with these regulations. As sustainability becomes a priority, construction firms are more inclined to adopt carbon fiber solutions for repairs. This regulatory landscape is expected to foster growth in the Carbon Fiber Construction Repair Market, as companies seek to comply with new standards while also appealing to environmentally conscious consumers. The emphasis on sustainability is likely to shape the future of construction repair.