Rising Labor Costs

The Bricklaying Robot Market is experiencing a notable shift due to the rising labor costs associated with traditional bricklaying methods. As skilled labor becomes increasingly scarce and expensive, construction companies are compelled to seek alternatives that can mitigate these costs. The integration of bricklaying robots offers a potential solution, as these machines can operate with minimal human intervention, thereby reducing labor expenses significantly. Reports indicate that labor costs in the construction sector have risen by approximately 20% over the past five years, prompting a reevaluation of operational strategies. Consequently, the demand for bricklaying robots is likely to increase as companies aim to enhance productivity while managing costs effectively.

Sustainability Initiatives

The Bricklaying Robot Market is witnessing a growing focus on sustainability initiatives within the construction sector. As environmental concerns gain prominence, construction companies are increasingly seeking methods to reduce waste and improve energy efficiency. Bricklaying robots can contribute to these sustainability goals by optimizing material usage and minimizing errors that lead to waste. Additionally, the precision of robotic systems allows for better control over resource consumption, aligning with the industry's shift towards greener practices. As sustainability becomes a key driver of business strategy, the adoption of bricklaying robots is likely to gain traction, reflecting a commitment to environmentally responsible construction.

Technological Advancements

The Bricklaying Robot Market is significantly influenced by rapid technological advancements in robotics and automation. Innovations in artificial intelligence, machine learning, and sensor technologies are enhancing the capabilities of bricklaying robots, making them more efficient and reliable. These advancements enable robots to perform complex tasks with precision, reducing the likelihood of errors and improving overall quality. Furthermore, the development of user-friendly interfaces allows for easier integration into existing construction workflows. As technology continues to evolve, the potential for bricklaying robots to revolutionize the construction process becomes increasingly apparent, attracting interest from various stakeholders in the industry.

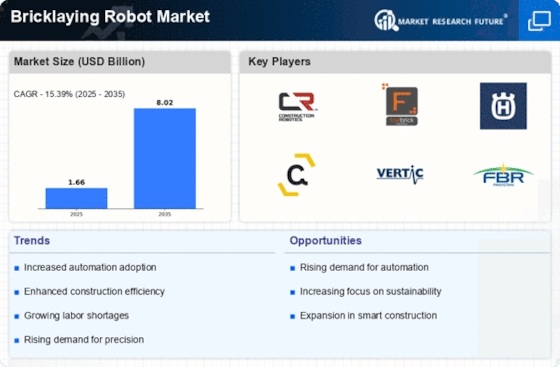

Growing Demand for Construction

The Bricklaying Robot Market is poised for growth, driven by the increasing demand for construction activities across various sectors. Urbanization and population growth are contributing to a surge in housing and infrastructure projects, necessitating efficient construction methods. According to recent data, the construction industry is projected to expand at a compound annual growth rate of 5% over the next five years. This growth creates a favorable environment for the adoption of bricklaying robots, which can expedite the construction process and improve overall project timelines. As construction companies strive to meet rising demands, the integration of robotic solutions appears to be a strategic move to enhance operational efficiency.

Focus on Safety and Risk Reduction

The Bricklaying Robot Market is also driven by an increasing emphasis on safety and risk reduction in construction environments. Traditional bricklaying poses various hazards, including falls, injuries from heavy lifting, and exposure to adverse weather conditions. The introduction of bricklaying robots can mitigate these risks by taking on physically demanding tasks, thereby protecting human workers from potential harm. As safety regulations become more stringent, construction companies are likely to invest in robotic solutions that enhance workplace safety. This trend not only improves worker well-being but also aligns with the industry's broader commitment to fostering safer construction practices.