Integration of Biomass in Energy Mix

The integration of biomass into the overall energy mix is becoming increasingly prominent, driving the Biomass Molding Fuel Market forward. As nations strive to diversify their energy sources and reduce reliance on fossil fuels, biomass is emerging as a viable solution. This trend is supported by advancements in technology that enhance the efficiency of biomass energy conversion processes. Market forecasts suggest that the biomass molding fuel sector could account for a significant share of the renewable energy market, potentially reaching 20% by 2030. This integration not only contributes to energy security but also aligns with global sustainability goals. The collaboration between governments, private sectors, and research institutions is likely to facilitate the development of innovative biomass solutions, further solidifying its role in the future energy landscape.

Regulatory Framework Supporting Biomass Energy

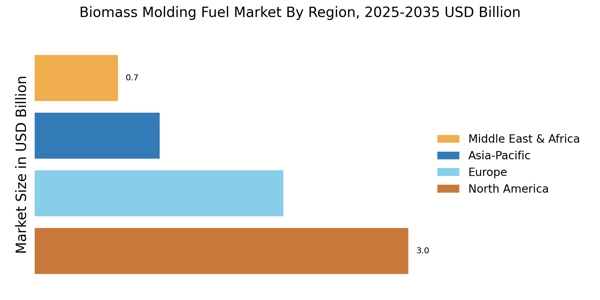

The Biomass Molding Fuel Market benefits significantly from supportive regulatory frameworks that promote renewable energy sources. Governments across various regions are implementing policies that incentivize the use of biomass as a sustainable energy alternative. For instance, renewable energy mandates and subsidies for biomass production are becoming more prevalent, encouraging investments in this sector. The market is expected to witness a robust growth trajectory, driven by these regulatory measures, which aim to reduce carbon emissions and enhance energy security. In many regions, biomass is recognized as a key component in achieving national energy targets, further solidifying its role in the energy mix. This regulatory support not only boosts market confidence but also attracts new players, thereby expanding the biomass molding fuel market landscape.

Economic Viability of Biomass as an Energy Source

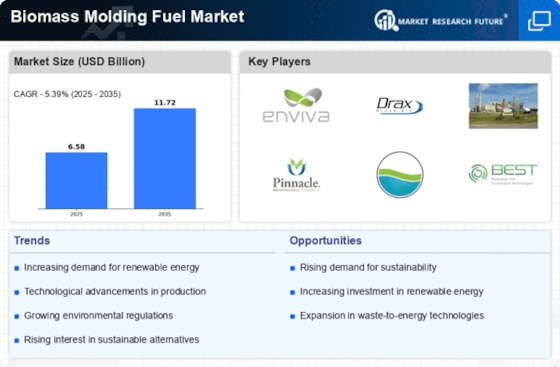

The economic viability of biomass as a renewable energy source is a crucial driver for the Biomass Molding Fuel Market. With fluctuating fossil fuel prices and the increasing cost of traditional energy sources, biomass presents a cost-effective alternative. The production of biomass molding fuel often utilizes agricultural residues and waste materials, which are abundant and inexpensive. This economic advantage is attracting investments and fostering the establishment of new production facilities. Market analysts project that the biomass molding fuel market could reach a valuation of several billion dollars within the next decade, as more stakeholders recognize the financial benefits of transitioning to biomass energy. Furthermore, the potential for job creation in rural areas through biomass production adds an additional layer of economic incentive, thereby reinforcing the industry's growth prospects.

Rising Consumer Awareness of Sustainable Practices

Consumer awareness regarding sustainable energy practices is on the rise, significantly impacting the Biomass Molding Fuel Market. As individuals and businesses become more environmentally conscious, there is a growing preference for renewable energy sources, including biomass fuels. This shift in consumer behavior is prompting manufacturers to adapt their offerings to meet the demand for eco-friendly products. Market data indicates that the demand for biomass molding fuel is expected to increase by 15% over the next few years, driven by this heightened awareness. Additionally, educational campaigns and initiatives aimed at promoting the benefits of biomass energy are likely to further enhance consumer acceptance. This trend not only supports the growth of the biomass molding fuel market but also encourages innovation in product development and marketing strategies.

Technological Innovations in Biomass Molding Fuel Production

The Biomass Molding Fuel Market is experiencing a surge in technological innovations that enhance production efficiency and reduce costs. Advanced processing techniques, such as torrefaction and pelletization, are being adopted to improve the quality and energy density of biomass fuels. These innovations not only streamline the manufacturing process but also contribute to higher yields and lower emissions. As a result, the market is projected to grow at a compound annual growth rate of approximately 8% over the next five years. This growth is indicative of the industry's potential to meet the increasing energy demands while adhering to environmental standards. Furthermore, the integration of automation and smart technologies in production facilities is likely to optimize resource utilization, thereby fostering a more sustainable biomass molding fuel ecosystem.