Consumer Preferences

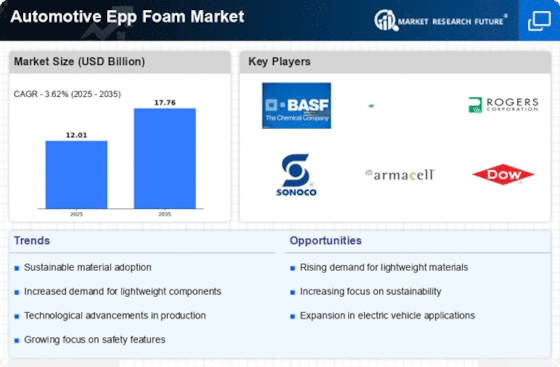

Consumer preferences are evolving, significantly impacting the Automotive Epp Foam Market. Today's consumers are increasingly seeking vehicles that offer enhanced comfort, safety, and sustainability. EPP foam, with its excellent cushioning properties and lightweight nature, is becoming a preferred material for automotive interiors and safety components. As automakers strive to meet these changing consumer demands, the integration of EPP foam into vehicle design is likely to increase. Market Research Future indicates that by 2025, consumer preference for lightweight and eco-friendly materials will drive a substantial portion of automotive material choices. This shift not only influences product development but also shapes marketing strategies within the industry. As a result, understanding and adapting to consumer preferences is essential for manufacturers aiming to thrive in the Automotive Epp Foam Market.

Regulatory Compliance

Regulatory compliance is a significant driver in the Automotive Epp Foam Market, as governments worldwide implement stringent regulations regarding vehicle safety and environmental standards. Manufacturers are compelled to adopt materials that meet these regulations, leading to an increased focus on EPP foam due to its favorable properties. EPP foam is not only lightweight and durable but also meets various safety standards, making it an attractive choice for automotive applications. In 2025, the emphasis on compliance with safety and environmental regulations is expected to intensify, further driving the demand for EPP foam in vehicle manufacturing. This regulatory landscape encourages innovation and investment in EPP foam technologies, as companies strive to enhance their product offerings while adhering to legal requirements. Consequently, regulatory compliance emerges as a pivotal factor influencing the Automotive Epp Foam Market.

Electric Vehicle Demand

The rising demand for electric vehicles (EVs) is a crucial driver for the Automotive Epp Foam Market. As automakers pivot towards electrification, the need for lightweight materials becomes paramount to enhance battery efficiency and extend driving range. EPP foam, known for its lightweight and energy-absorbing properties, is increasingly being utilized in EV applications, including battery enclosures and interior components. The Automotive Epp Foam Market is projected to grow exponentially, with millions of EVs expected to be on the roads by 2025. This surge in EV production is likely to create substantial opportunities for EPP foam manufacturers, as they cater to the evolving needs of the automotive industry. The integration of EPP foam in electric vehicles not only aids in weight reduction but also contributes to improved safety and performance, solidifying its role in the Automotive Epp Foam Market.

Technological Innovations

Technological innovations are reshaping the Automotive Epp Foam Market, as advancements in manufacturing processes and material science enhance the performance of EPP foam. Innovations such as improved molding techniques and the integration of smart materials are enabling manufacturers to produce EPP foam with superior properties, including enhanced durability and impact resistance. The market is witnessing a surge in demand for high-performance EPP foam, particularly in safety applications such as crash protection and energy absorption. In 2025, the market for advanced automotive materials is expected to reach new heights, with EPP foam being a key component in the development of next-generation vehicles. These technological advancements not only improve vehicle safety but also contribute to overall vehicle performance, making them a significant driver in the Automotive Epp Foam Market.

Sustainability Initiatives

The Automotive Epp Foam Market is increasingly influenced by sustainability initiatives. Manufacturers are under pressure to adopt eco-friendly materials and processes, which has led to a rise in the use of expanded polypropylene (EPP) foam. This material is recyclable and lightweight, contributing to reduced vehicle weight and improved fuel efficiency. As consumers become more environmentally conscious, automakers are prioritizing sustainable practices, which is likely to drive demand for EPP foam. In 2025, the market for sustainable automotive materials is projected to grow significantly, with EPP foam playing a crucial role in meeting regulatory requirements and consumer expectations. The shift towards sustainability not only enhances brand reputation but also aligns with global efforts to reduce carbon footprints, making it a pivotal driver in the Automotive Epp Foam Market.